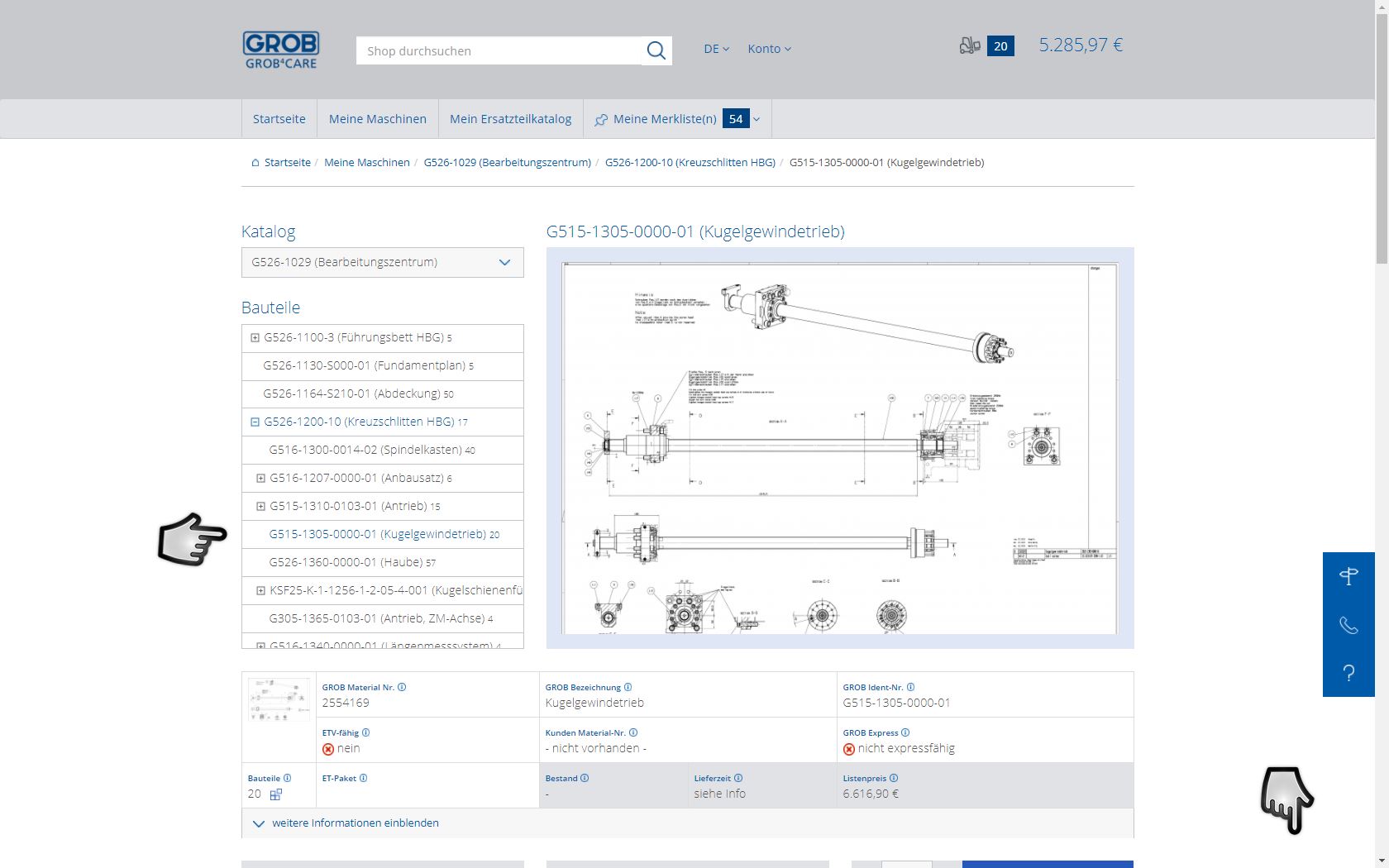

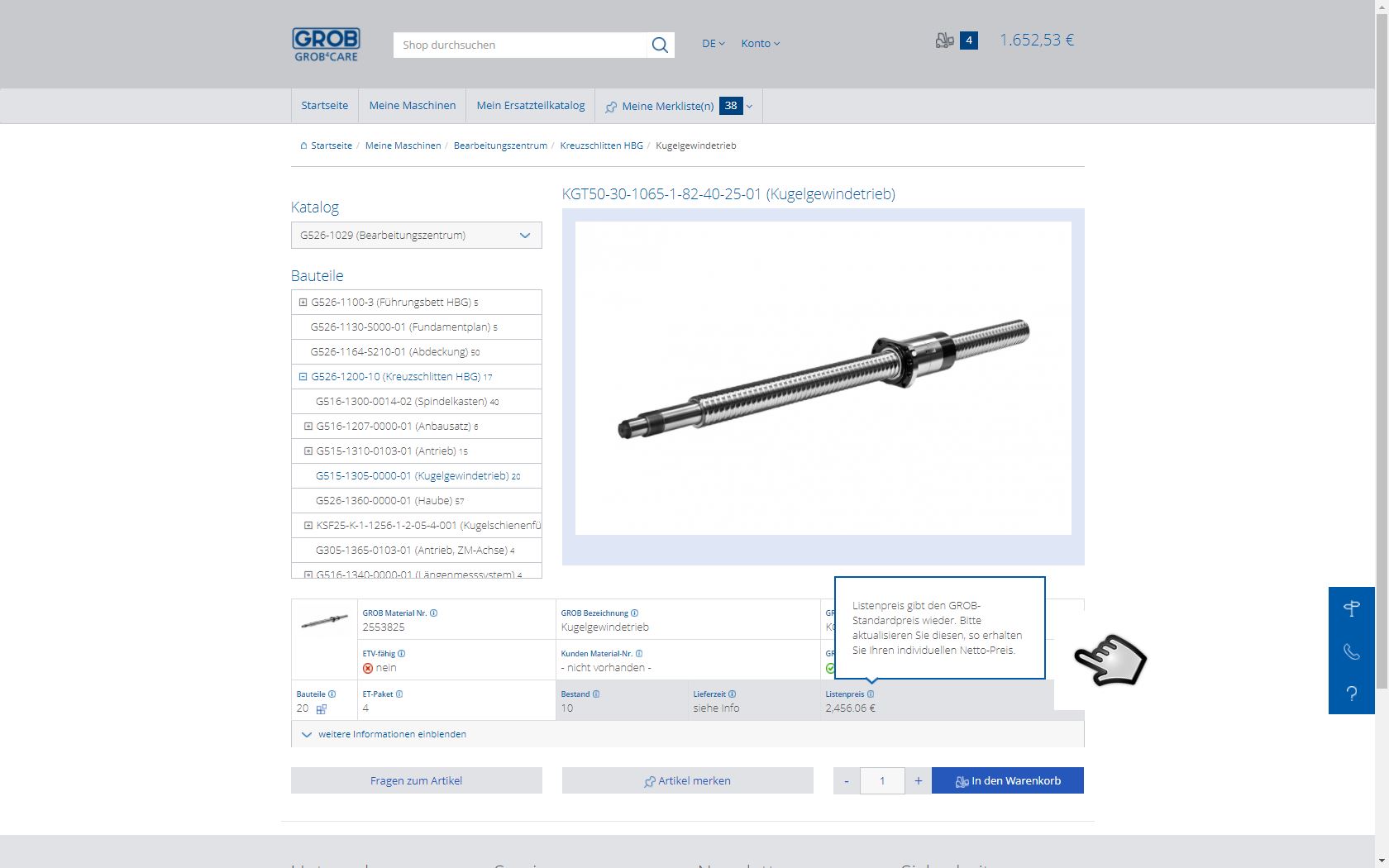

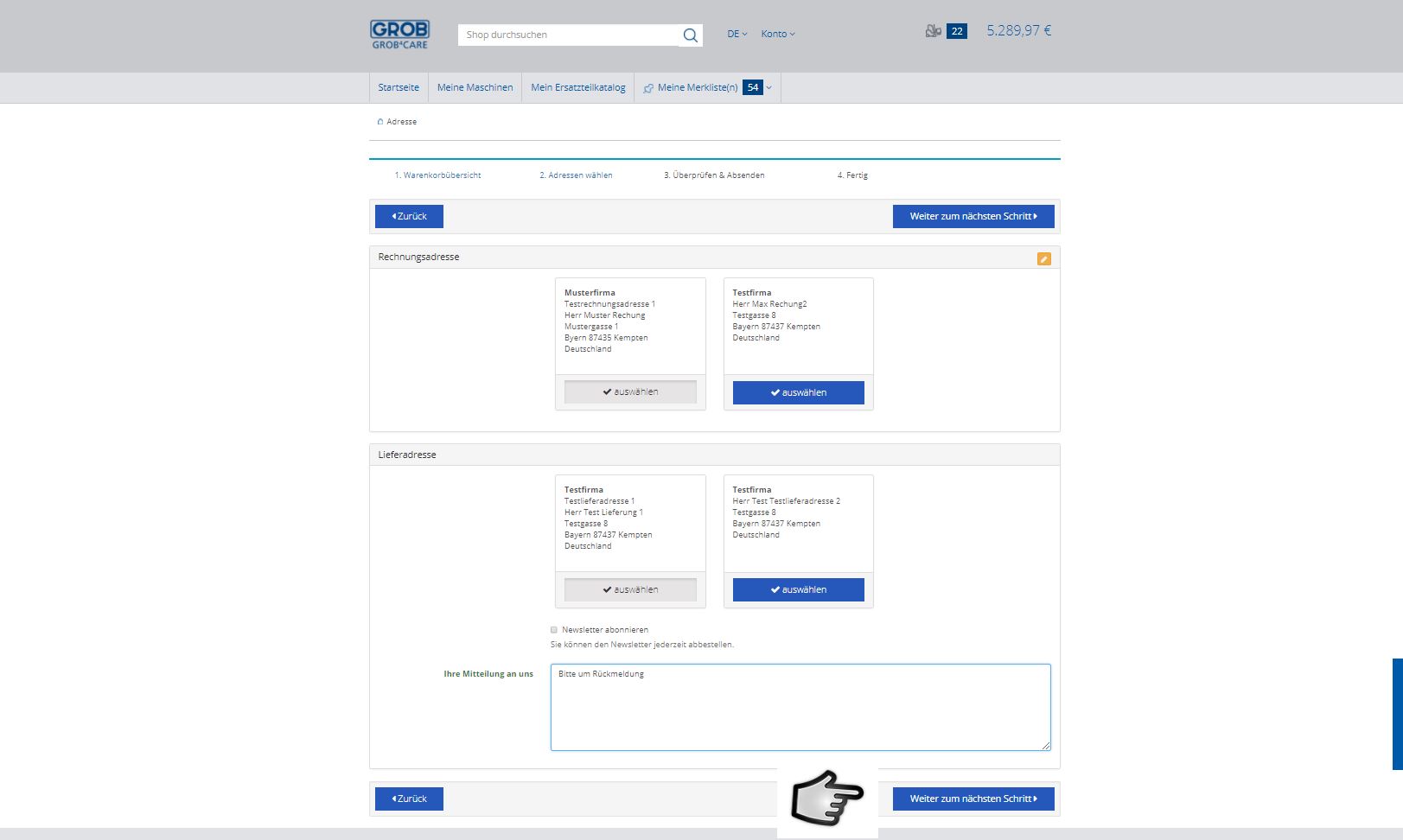

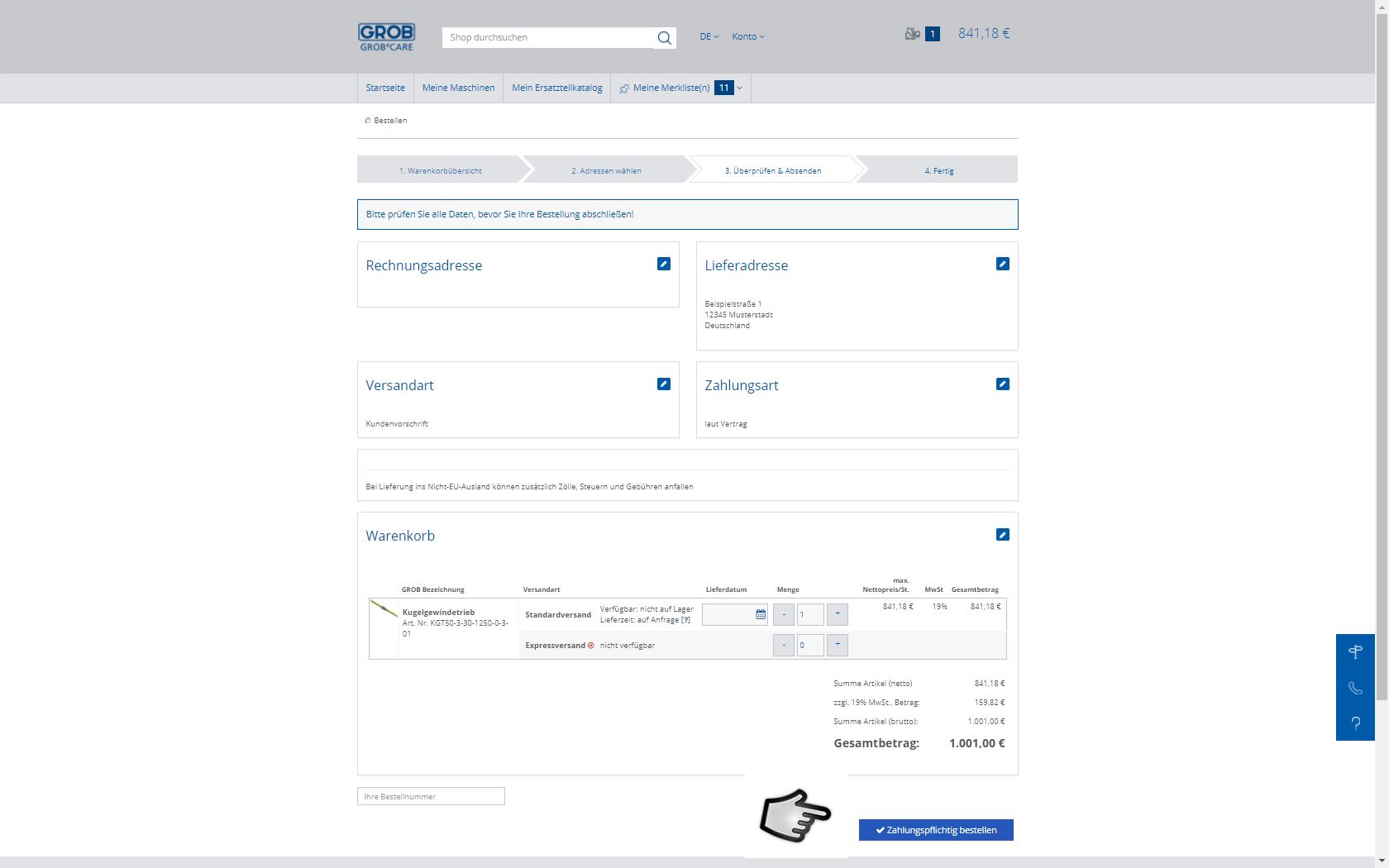

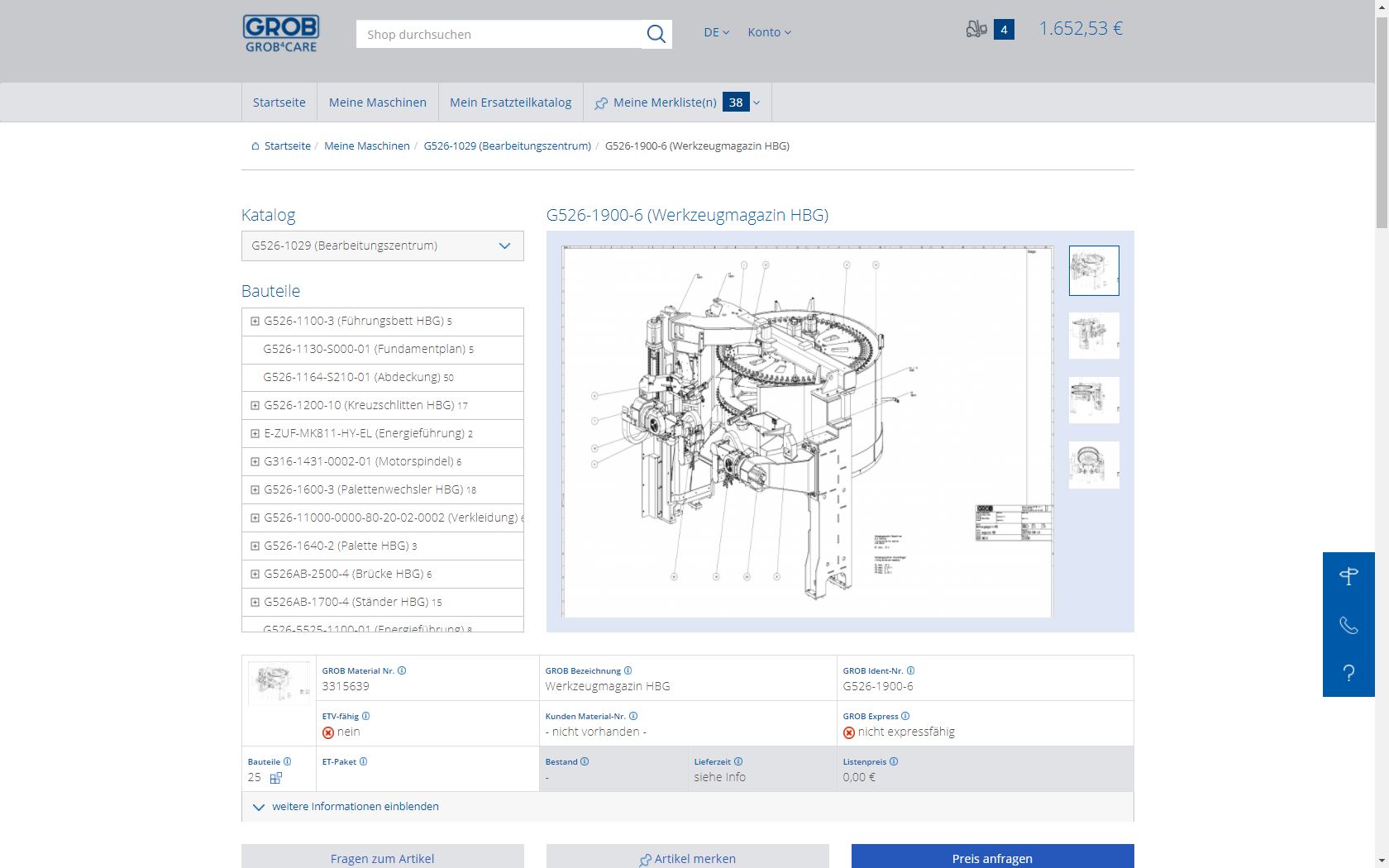

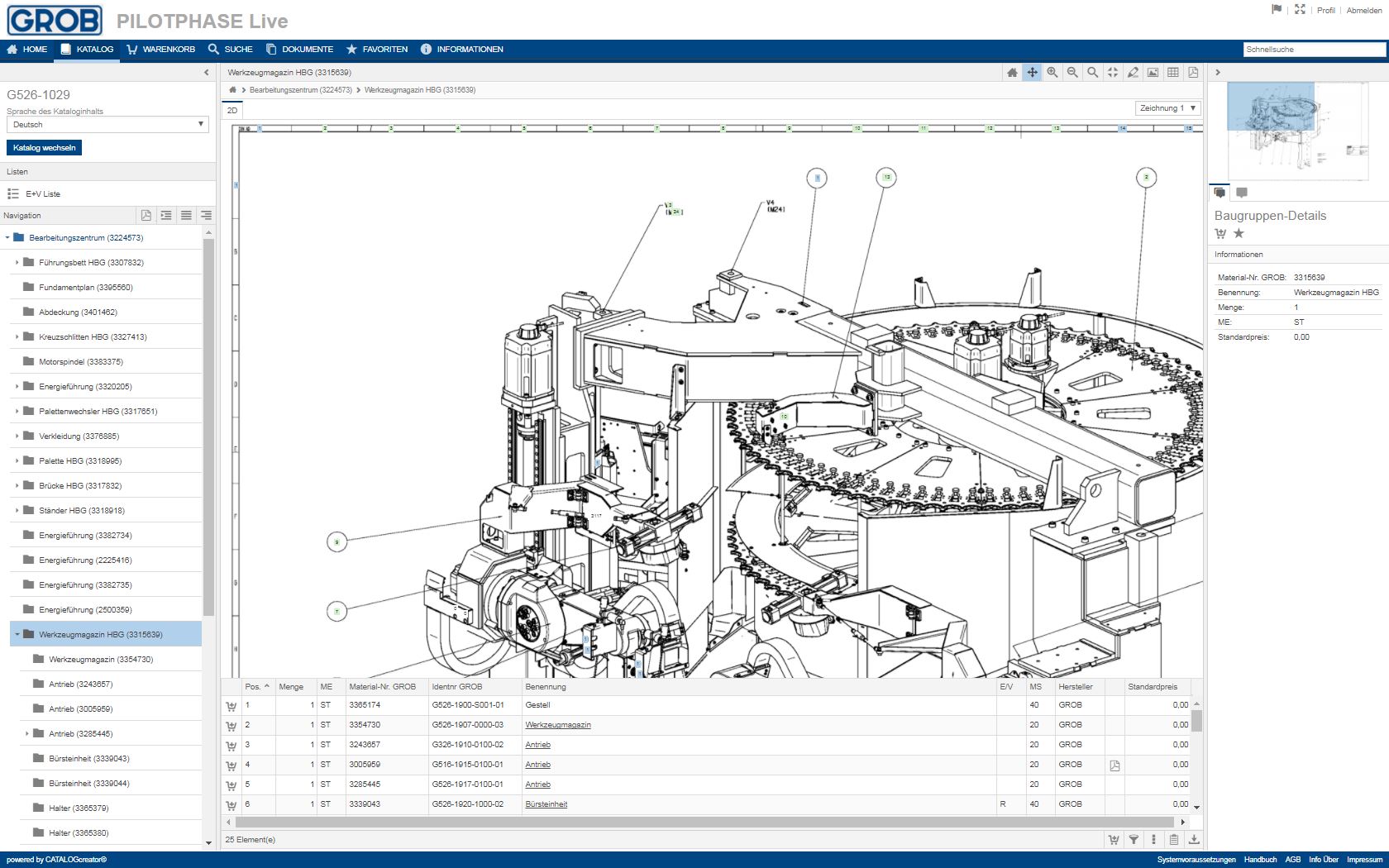

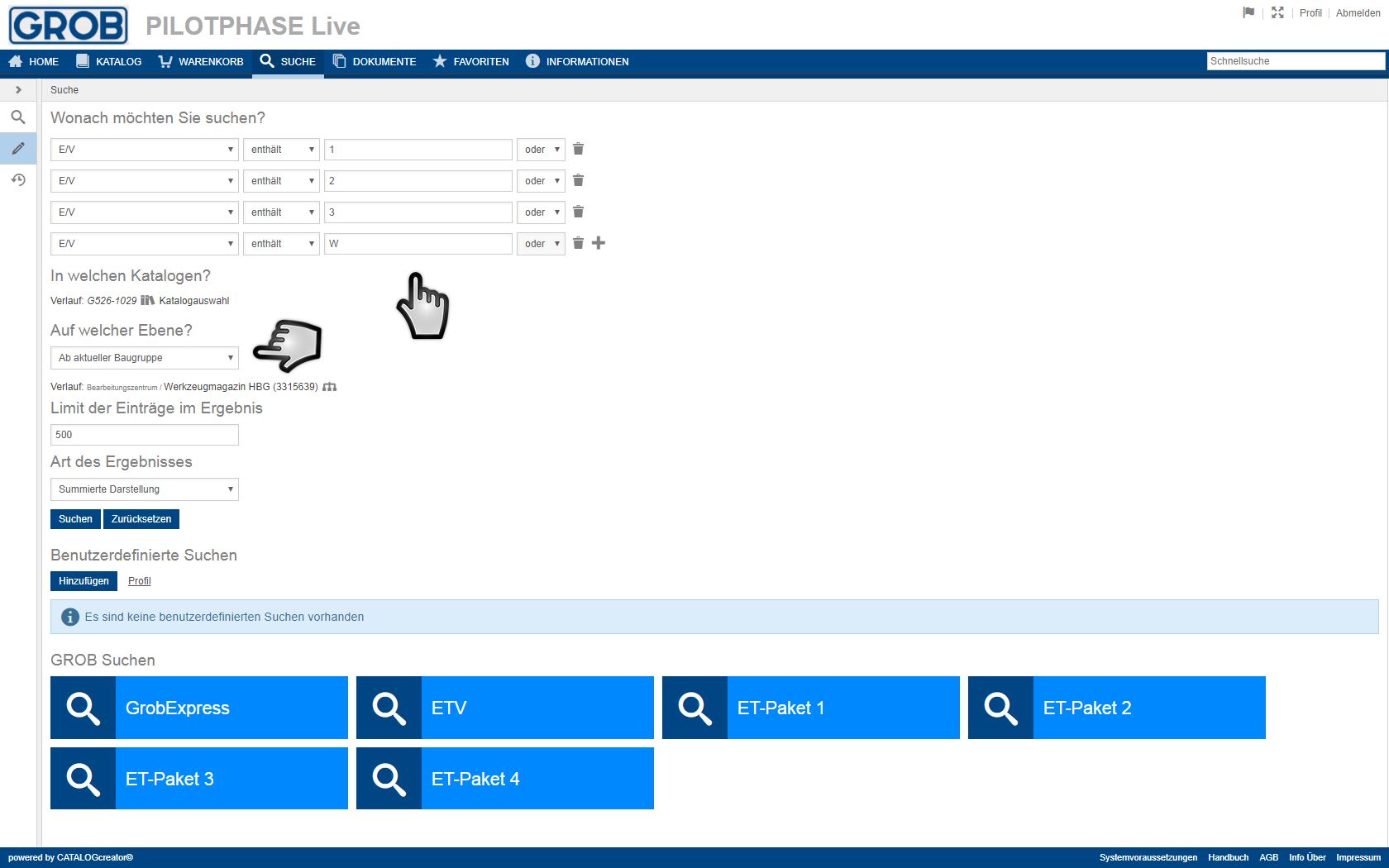

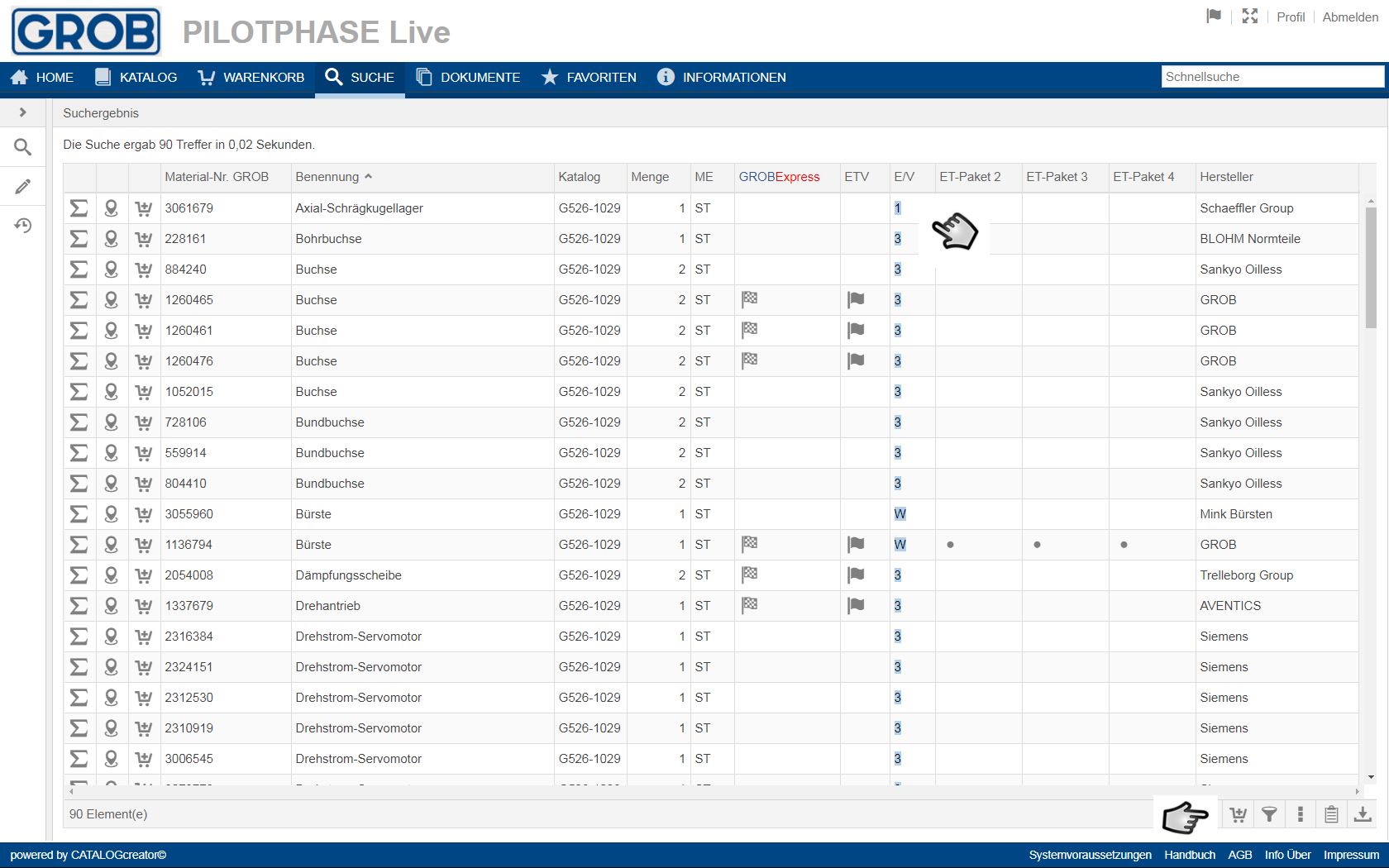

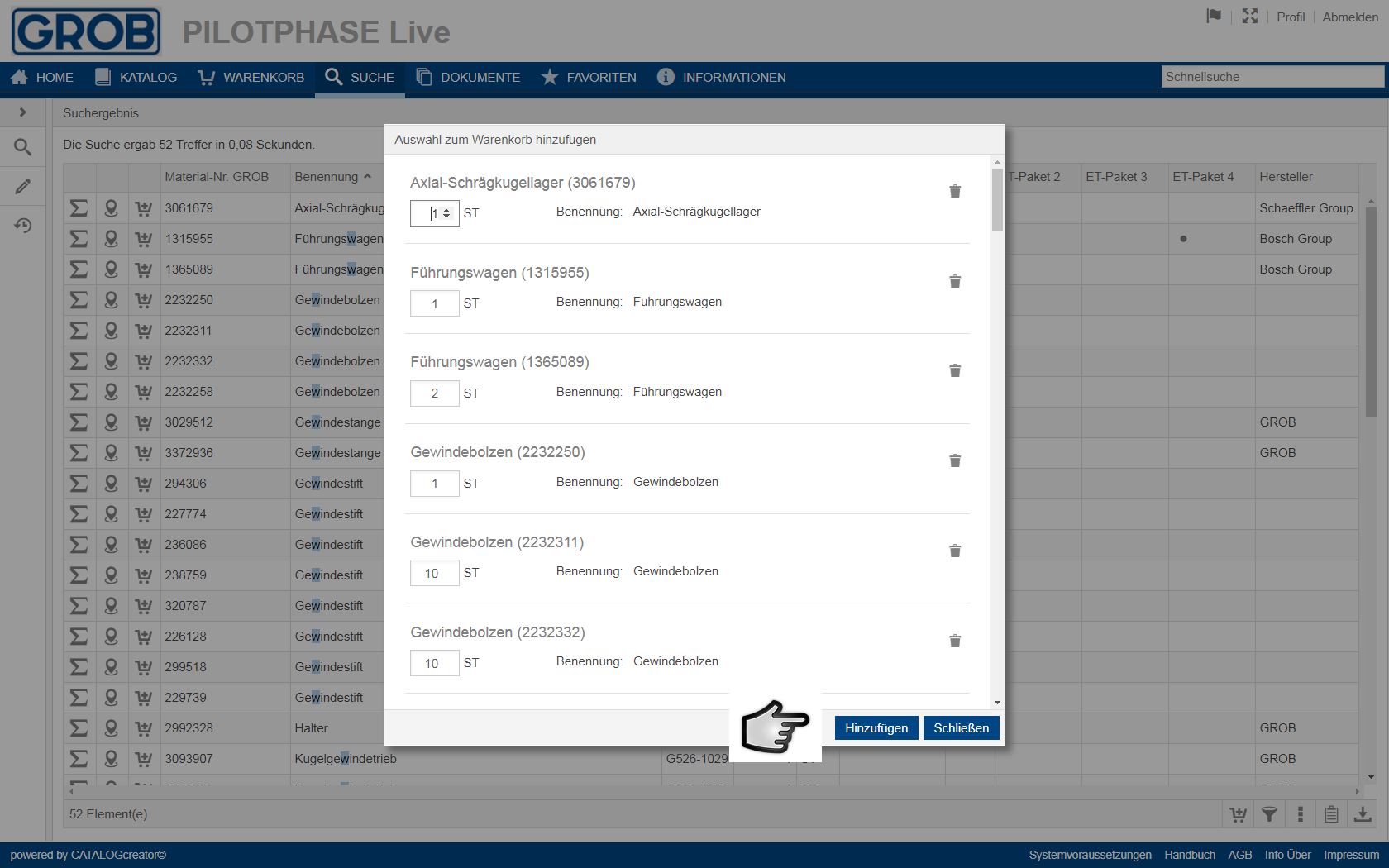

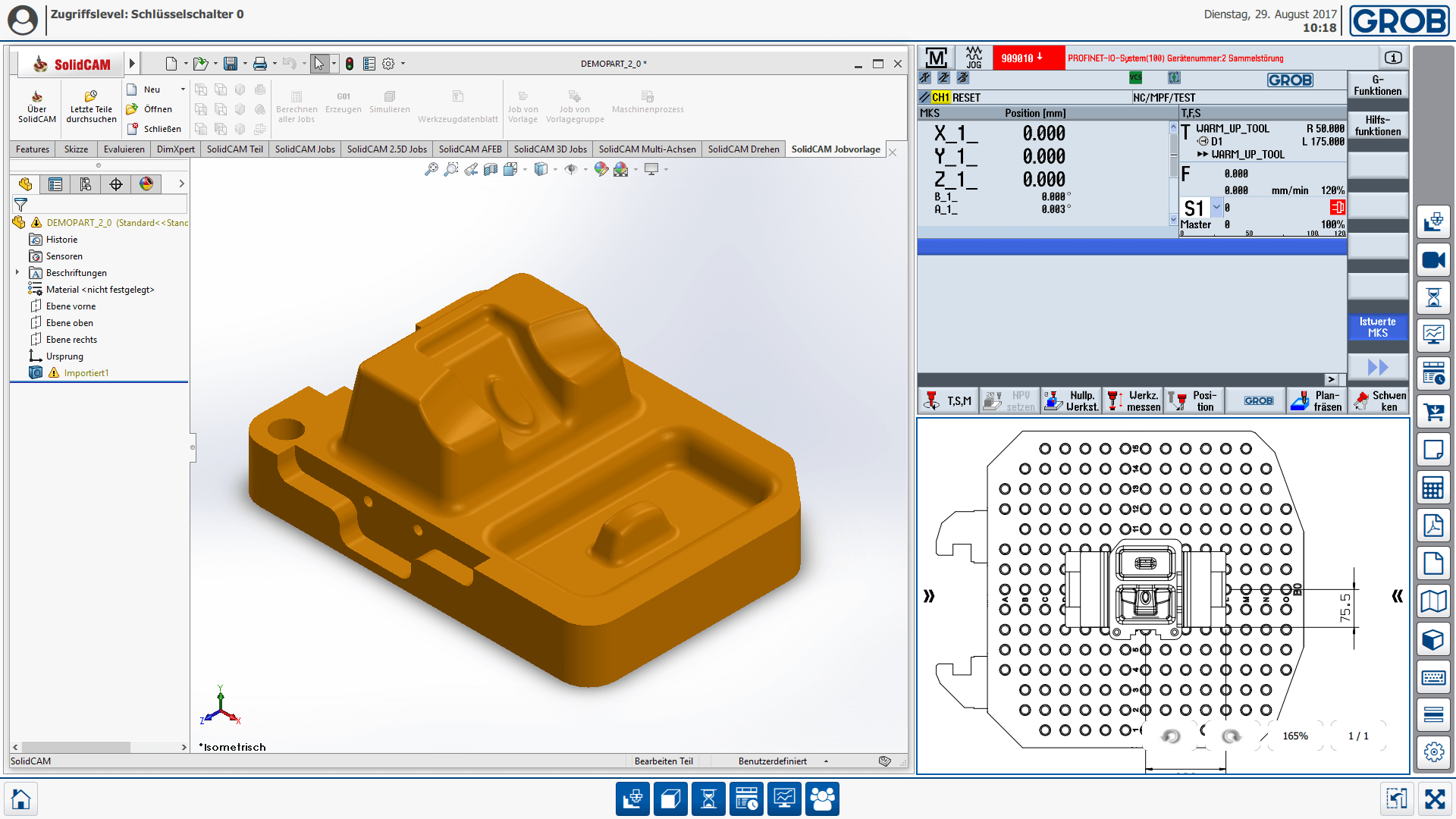

The machine in sight

via smartphone

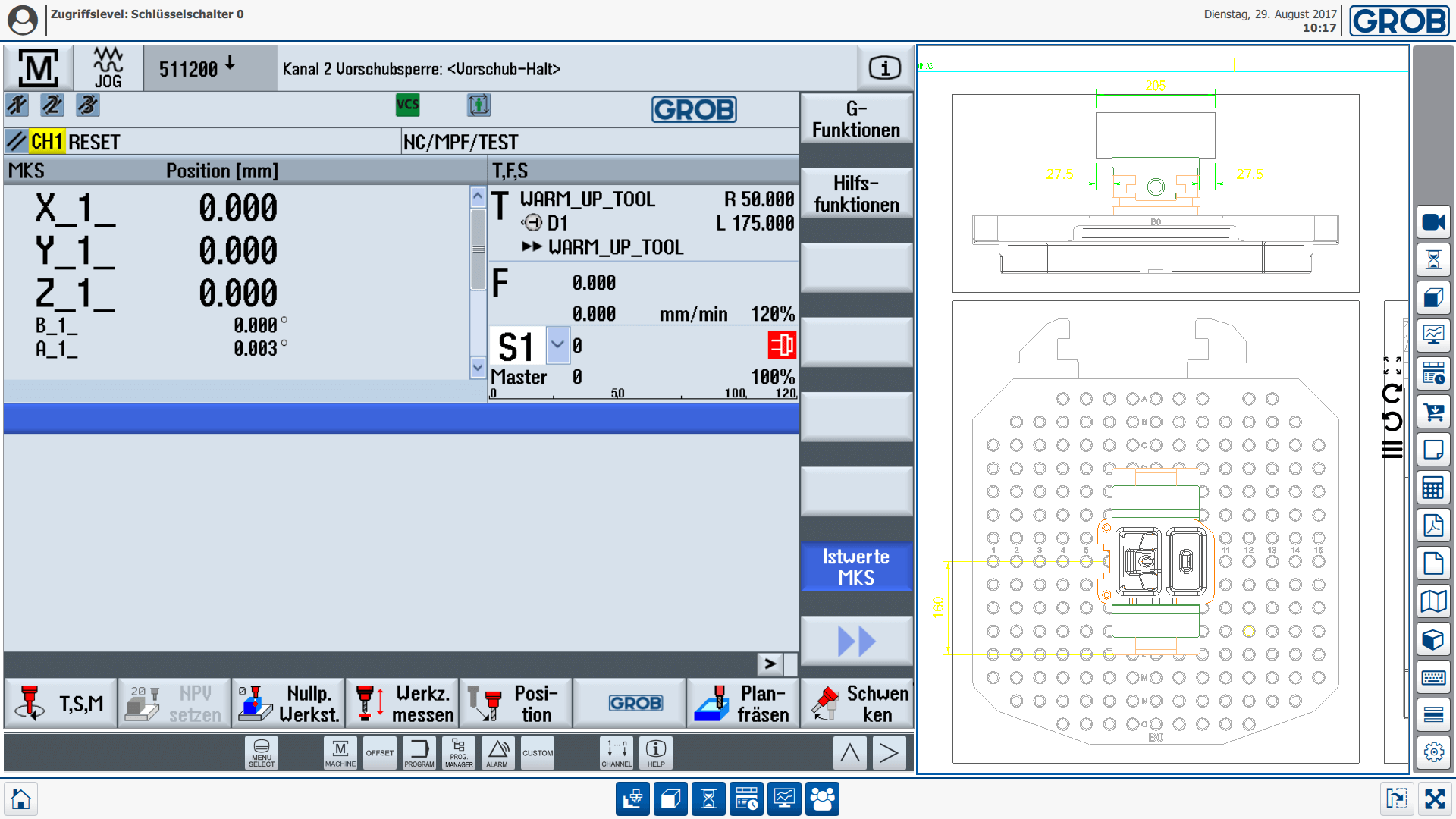

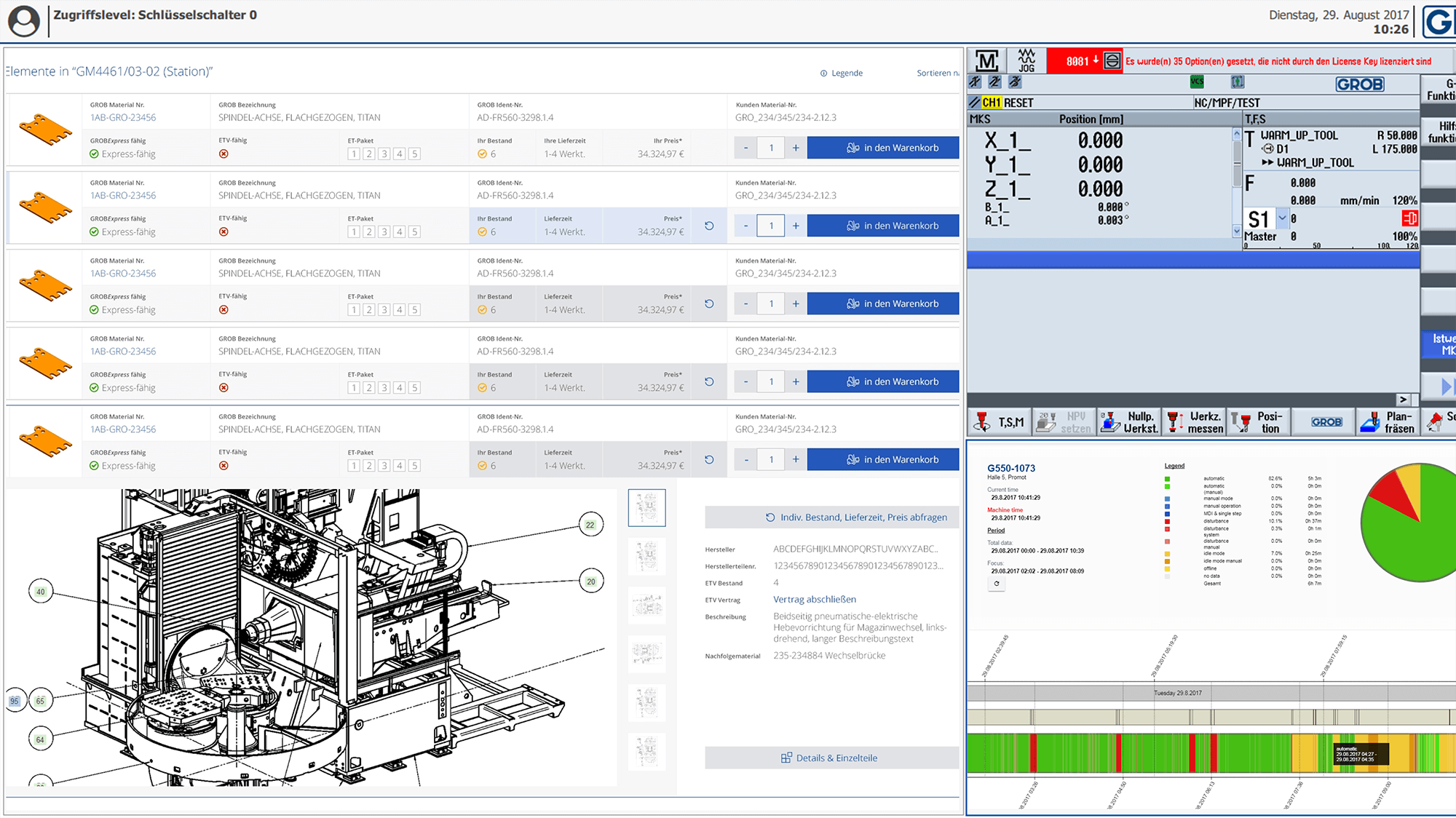

With the GROB4Line module, the GROB machine is connected to the Internet and as such can be monitored and controlled by an approved computer or smartphone. The notification function that sends messages, such as "End of job" or "Machine down-time", to defined smartphones or computers, allows the technician in charge to respond immediately and minimize unnecessary down-times.

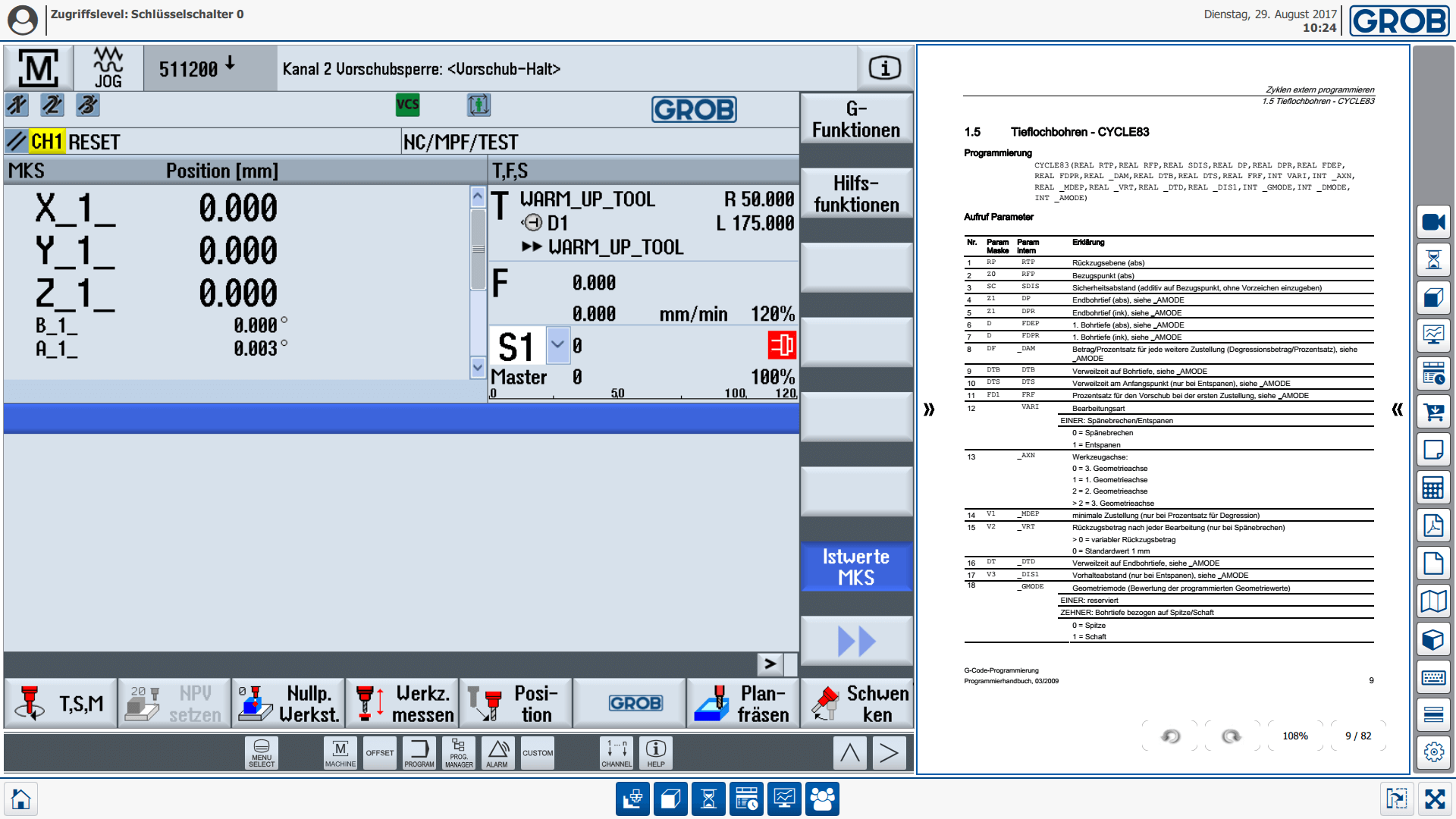

GROB4Line-functionalities:

on your smartphone

- Mobile access to your machines

- Automatic notification at the end

of a job or if problems arise - Actual status monitoring

- Latest status, fault and program information live at a glance

- Historical run-time bar

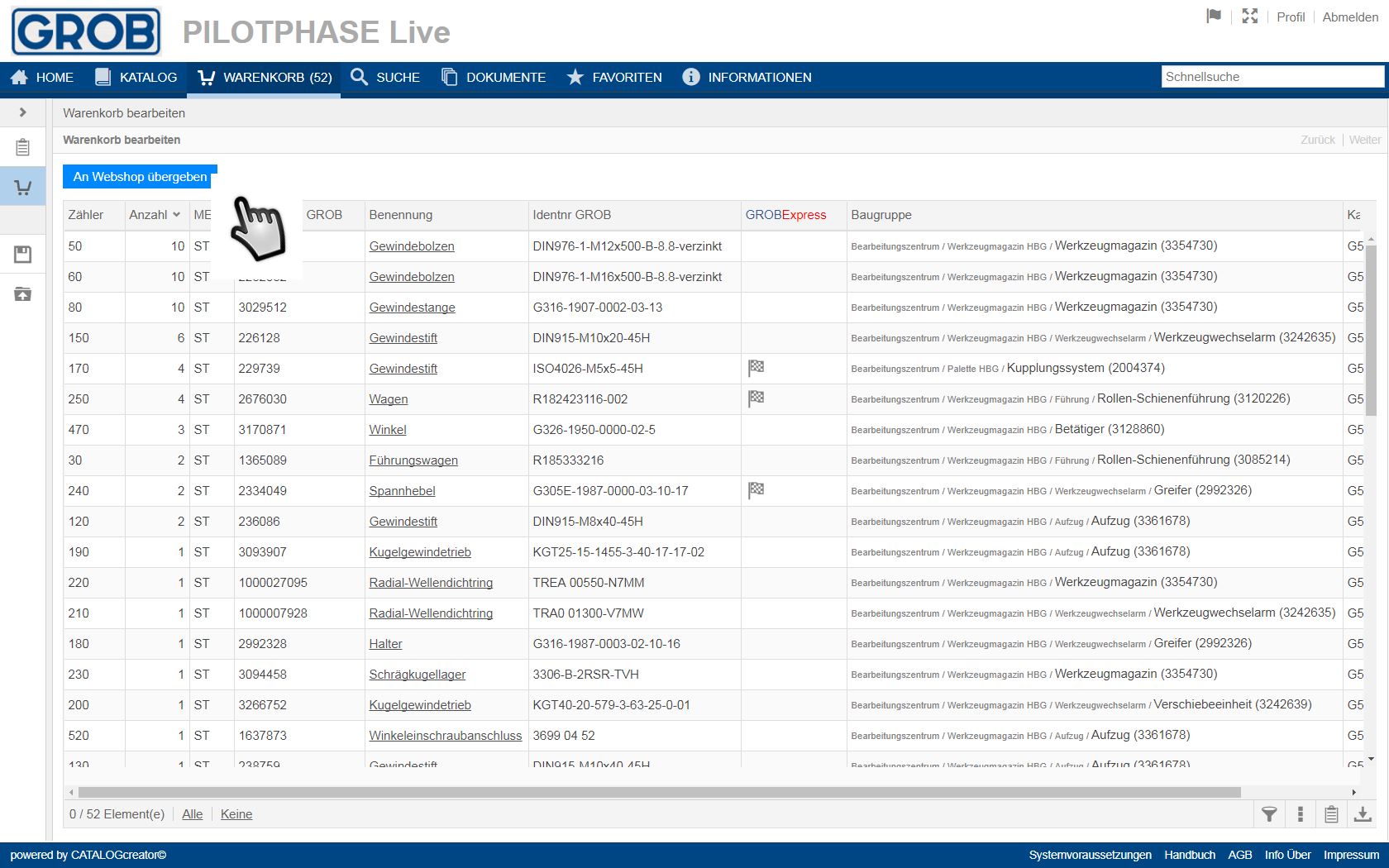

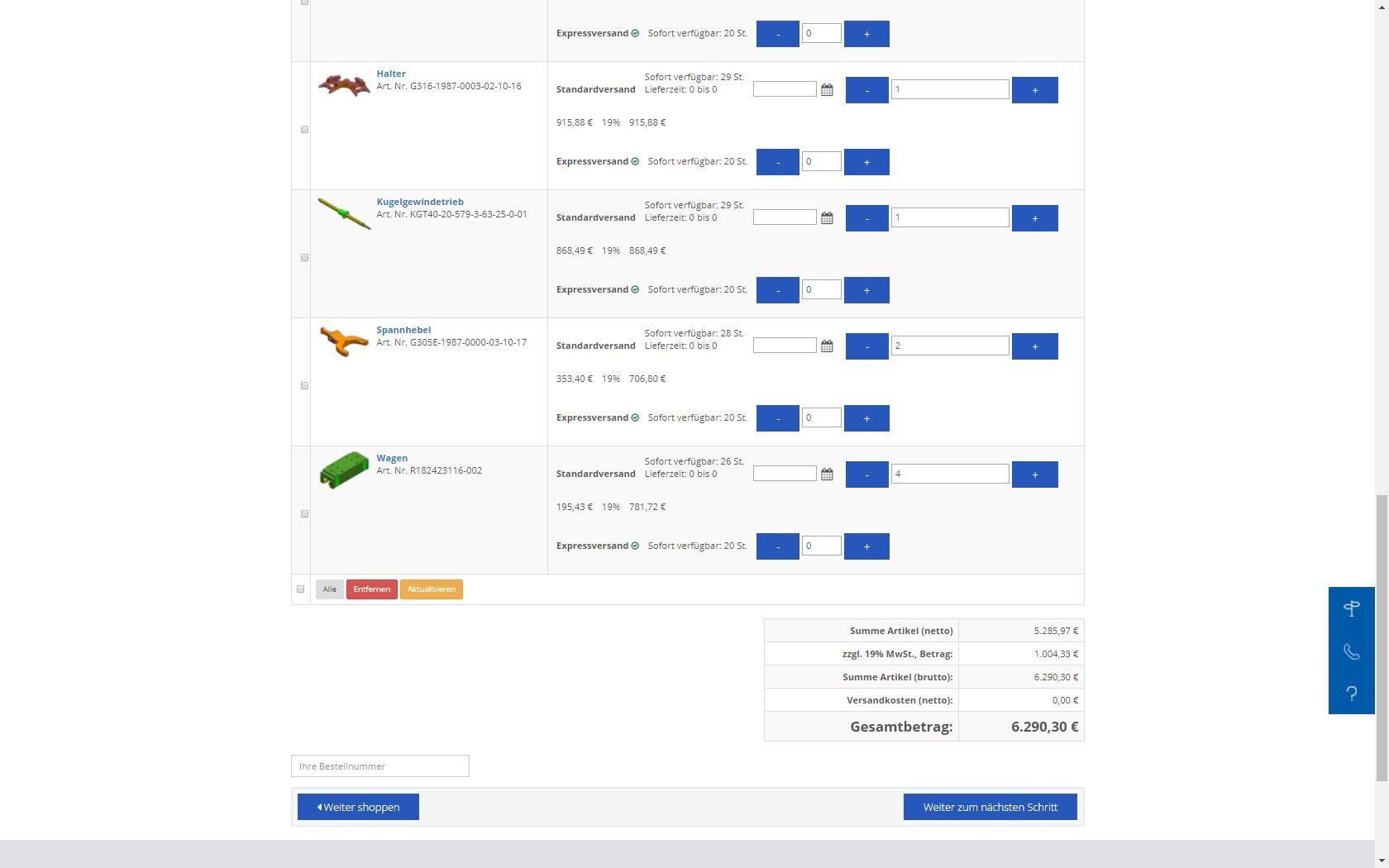

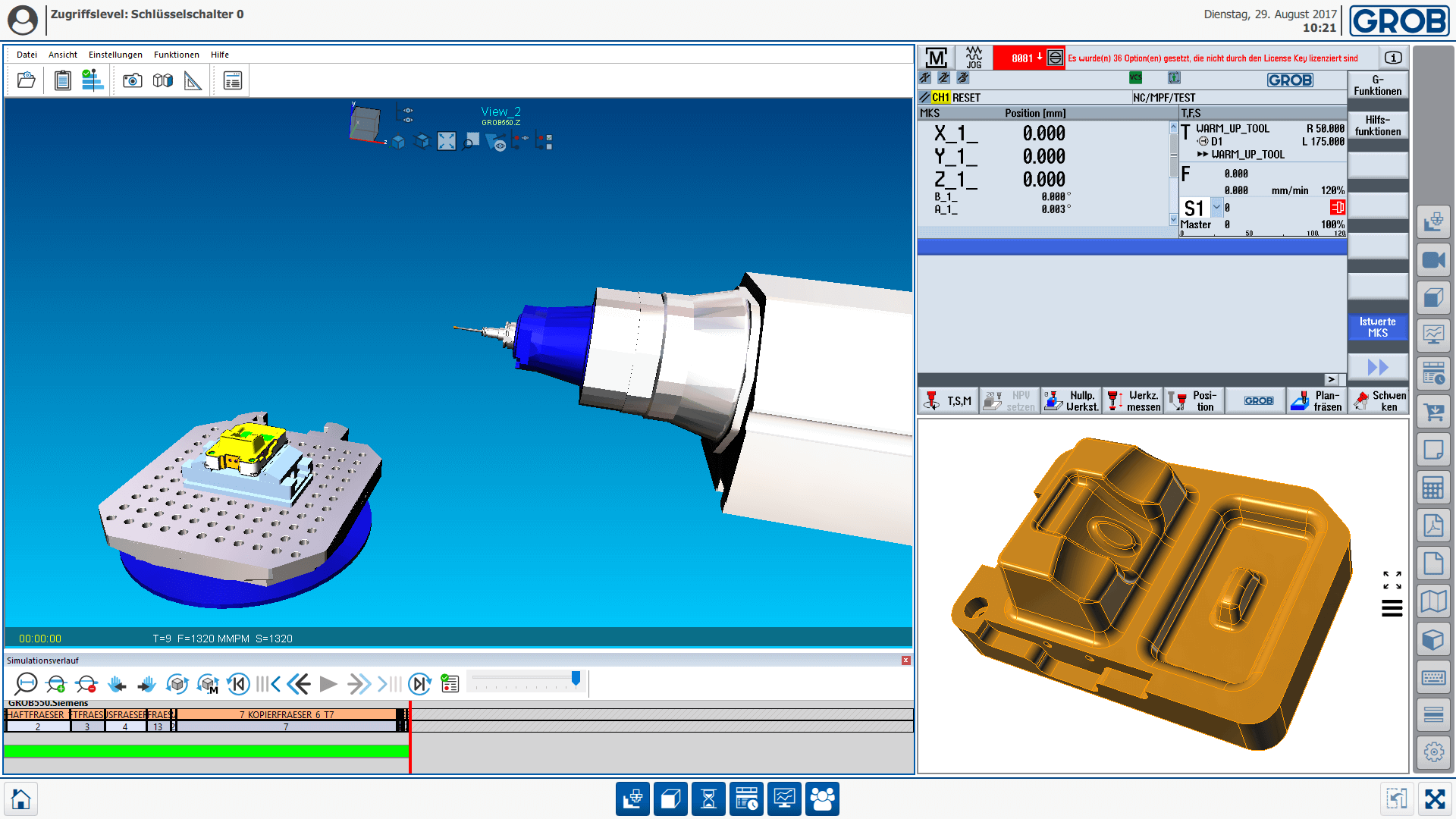

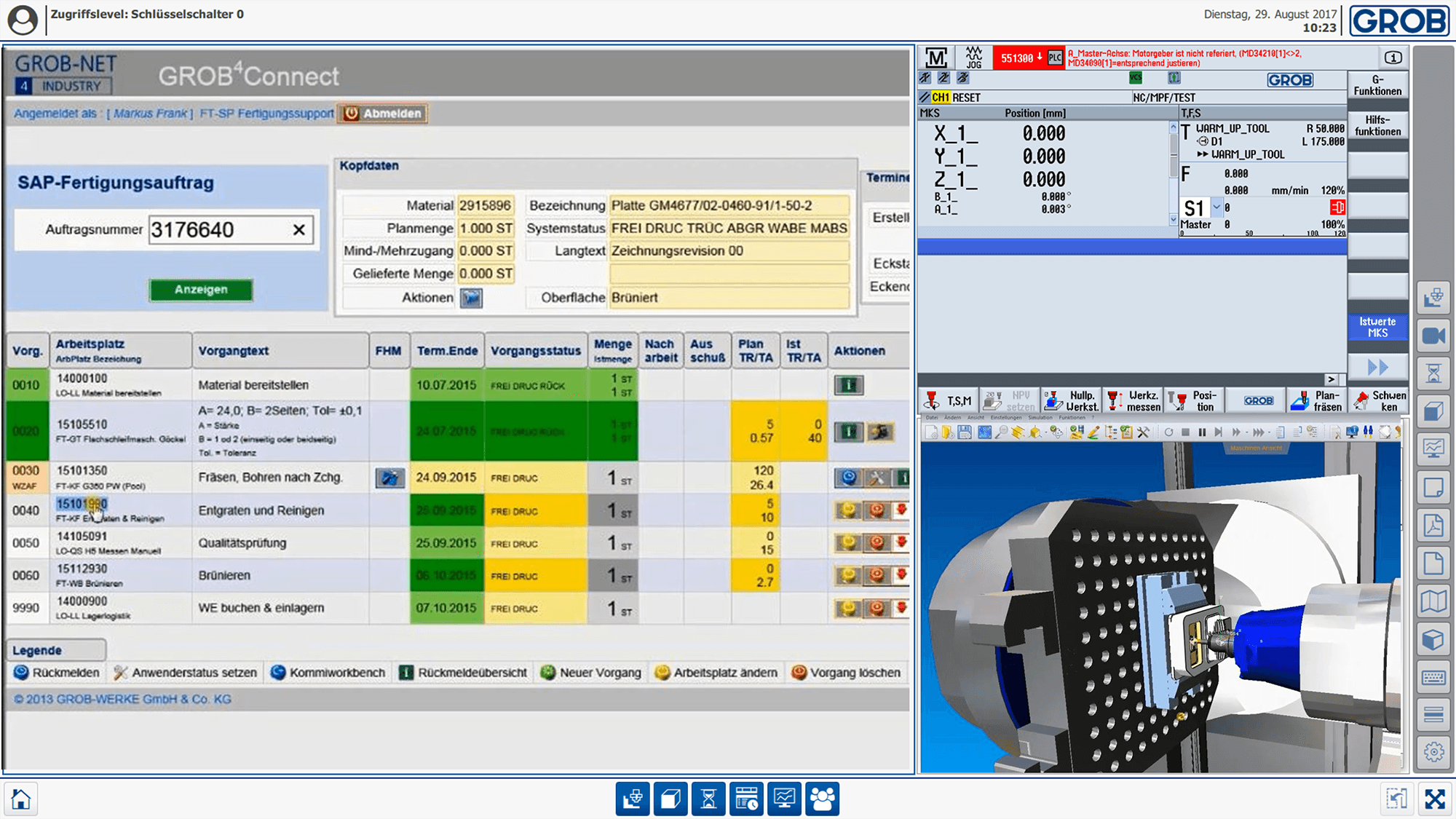

GROB4Line live in operation

GROB4Line – the benefits to you

- Support for reducing down-times

- Unmanned monitored production

at the weekend and overnight - More dependable planning with

real-time monitoring on the machine - Support for site independence

- Machine can be started via remote control before work commences

Your value-added package

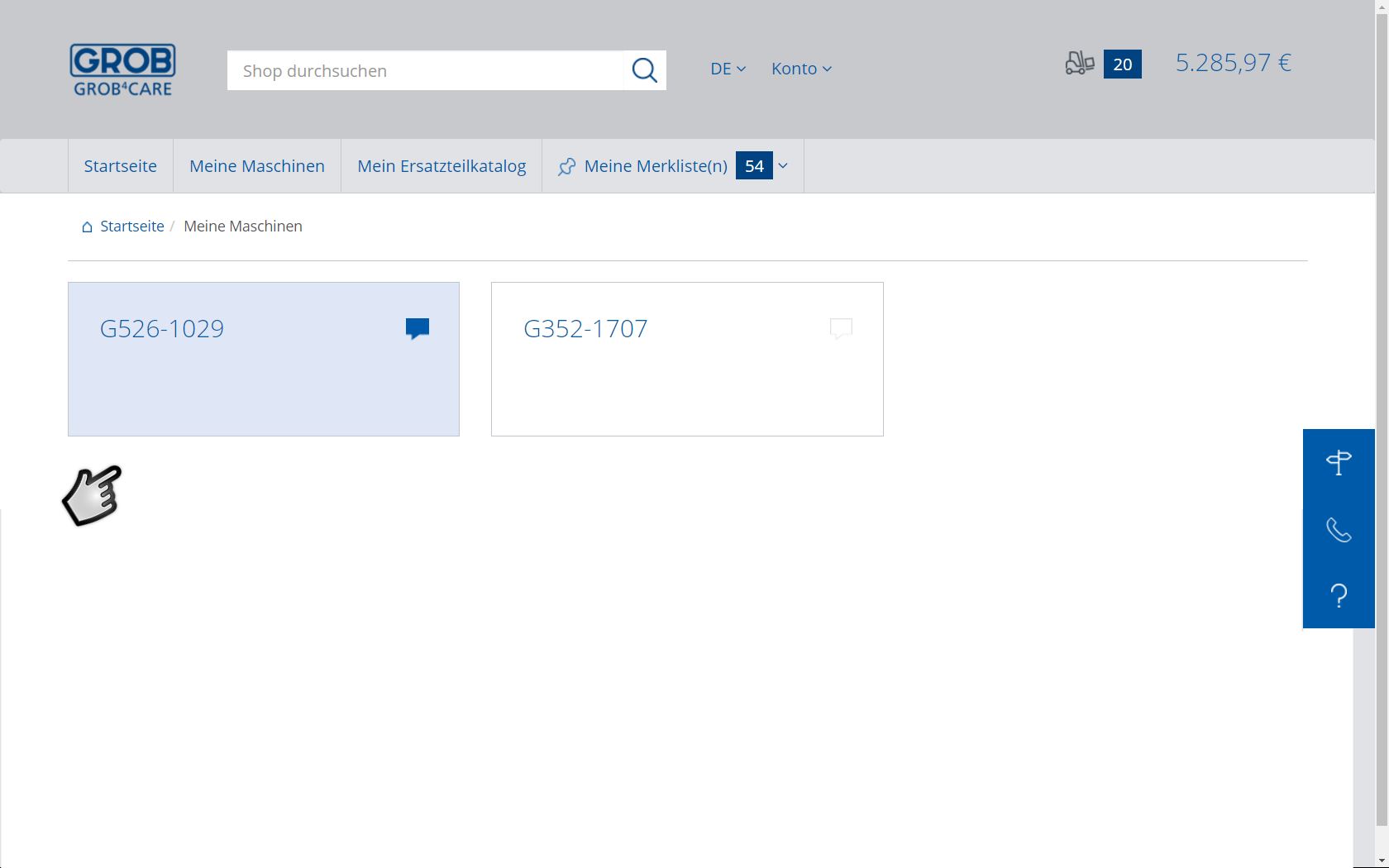

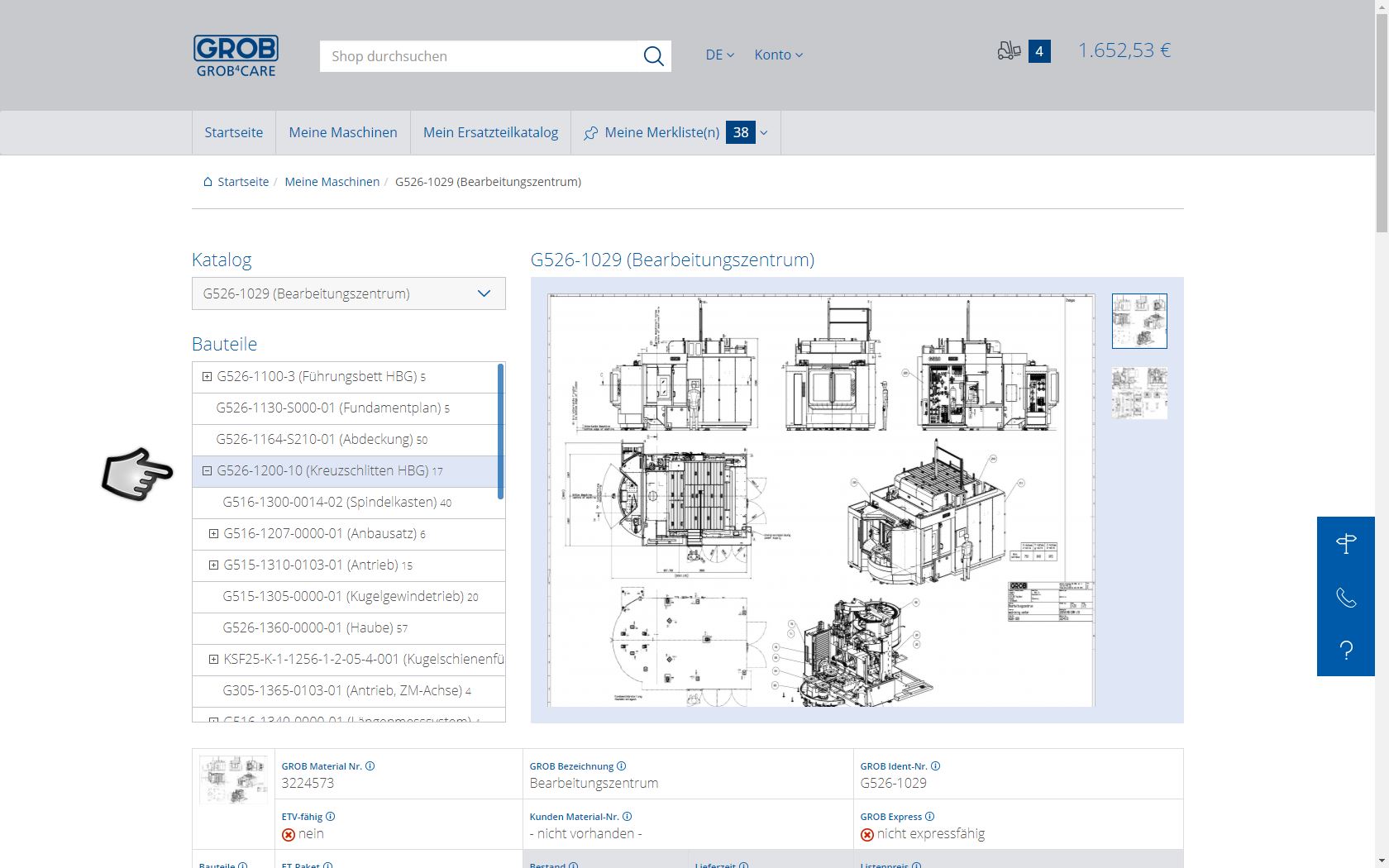

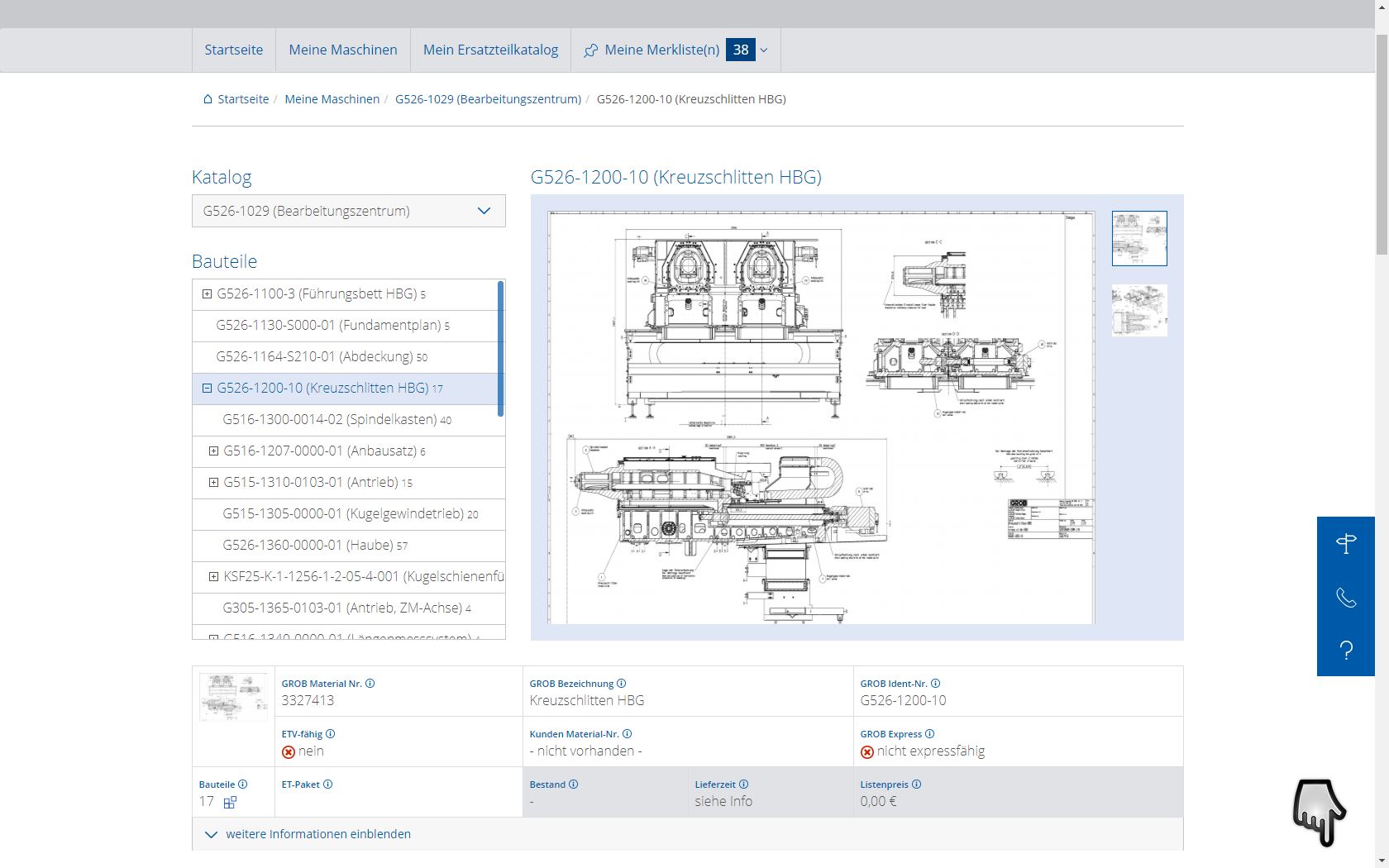

Simple and intuitive remote

access to your machines