Located near the Luxembourg border, thyssenkrupp Automotive Body Solutions has been supplying the automotive industry with its standardized and flexible solutions as an integrated body builder for decades. The company, founded 125 years ago, is known on the market for speed, know-how and quality, so it is only logical that thyssenkrupp Body Solutions expects the same from its suppliers. GROB already noticed this in 2008 during the first project with thyssenkrupp Body Solutions.

Initial experience with GROB flexibility and technology know-how

At the end of 2008, thyssenkrupp Automotive Body Solutions invested in its first automation system with integrated 5-axis milling center. A robotic automation system that was equipped with combined pallet and workpiece handling, as well as the possibility to integrate a second machine. Ten years later, this automation was then to be expanded with a second 5-axis milling center. "Here GROB was the only company willing and able to help us. Especially since there were already problems with the automation at that time," remembers very clearly the Production Manager of thyssenkrupp Automotive Body Solutions, Thomas Hahn, who with his 40 years of professional experience is an old hand in mechanical engineering. "And by the way, this order was the first time we were able to convince ourselves of GROB's flexible, but also technologically impressive approach."

The solution was found with a GROB G550. After extensive tests, with additional integration of a new control system from PROCAM, it was integrated into the existing plant both mechanically and in terms of control technology.

Completely new challenges with a second order

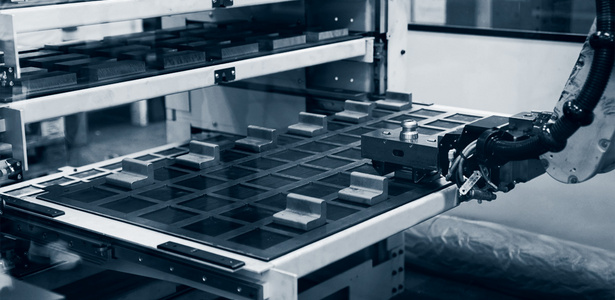

The challenge for GROB's tender designers was even more intensive and extensive for the second, extremely demanding task from thyssenkrupp Automotive Body Solutions. For its small parts series production, the company planned the acquisition of a 5-axis milling center including automation, with which a wide variety of workpieces can be flexibly produced in two setups, but also special parts can be manufactured. Despite the difficult conditions caused by Corona at the time, GROB managed to successfully cooperate with thyssenkrupp Automotive Body Solutions and closely coordinate with regard to an optimal automation solution. As with the first automation, PROCAM's control software technology was to be used for this system as well. For this order, too, the primary objective was to find an overall concept based on the customer's requirements. "So in this application we not only had to meet the requirement of a flexible partial spectrum, but also as a general contractor we had to find a clever system of how to coordinate our G350 Access, the GRESSEL R-C2 clamping system and the control software from PROCAM with the customer's requirements," GROB Technical Proposal Ralph Birkle explains the initial situation.

GROB G350 Access, GRESSEL R-C2 and PROCAM provide the optimal solution

Thus, in close cooperation with thyssenkrupp Automotive Body Solutions, the desired automation and a part spectrum were first specified. The robot gripper from GRESSEL was used for the required six-sided machining of the unmachined part, since it can be inserted into the machine once as a gripper and simultaneously as a clamping system. This means that there is no need for pallets or many different grippers, since in principle the robot with a large stroke can adjust the gripper to very different workpieces. In sum, this system is not only highly flexible, but can also handle many different workpieces with just a few grippers. The robot, which can change grippers with its front interface, places the first gripper in the machine and uses another gripper to pick up the next workpiece from the station. This is then bolted to the gripper in the machine by the robot, processed and changed via a zero-point clamping system. "At this point we favored the use of a pallet changer so that loading and unloading of the GRESSEL clamping equipment is possible in parallel with machining time, and machine waiting times can be reduced to a minimum" explains GROB area sales manager Jürgen Rieger. Another advantage of the system is that directly after the first machining operation, the robot takes the clamp out of the pallet changer in parallel and moves to a reclamping station where another gripper is already located at the bottom. Now it unhooks the gripper at the top, moves down and transfers the part, rotated by 180 degrees, to the changeover gripper. This is how the changeover from OP10 to OP20 is created. The pallet changer thus not only reduces waiting times, but also enables the many gripper changes to run one after the other.

Through intensive cooperation to a successfully running system

Developing an overall concept for such an automation system is one thing. Getting it up and running can only be done as a team, with an intensive exchange at eye level among each other and with a lot of know-how and experience. This successfully producing automation system is the result of intensive cooperation between GROB, GRESSEL, PROCAM and thyssenkrupp Automotive Body Solutions.