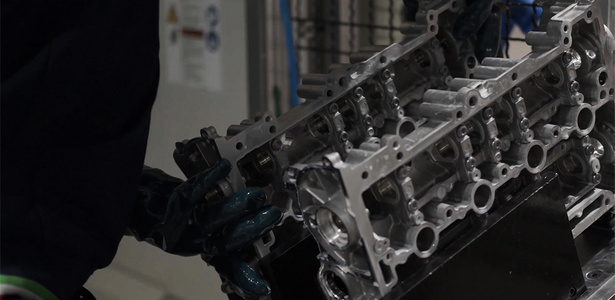

Endurance SpA is a European company within Endurance Technologies Ltd and specializes in aluminum die casting and machined components for leading European OEMs. The focus is clearly on powertrain products. Andrea Tarditi explains: "We concentrate on components for thermal engines, hybrid drives, electric motors for electromobility, and new PHEV/MHEV gearboxes." Endurance thus plays an important role in a market that is currently undergoing major changes and is increasingly characterized by disruptive technologies.

The beginning of a long-standing collaboration in 2009

The first points of contact with GROB came in 2009, when GROB began offering the first single-spindle G-module specifically for Tier 1 suppliers. "With the support of GROB's representative SIMU in Turin, we were quickly able to establish a direct connection with GROB. That was the start of our initial discussions about machine investments and complete production lines," recalls Tarditi.

A decisive step was Endurance's visit to various VW plants in Germany: "We were able to see GROB machining lines in full production and get direct feedback from the production managers at VW. This experience was crucial for us in successfully planning our future projects," explains Tarditi.

Technical expertise, consistent project management, and a strong team

When Andrea Tarditi talks about the collaboration with GROB, it quickly becomes clear that this partnership is not only based on technology—it is based on trust, expertise, and a shared vision for the future of mobility.

Several factors were decisive for Endurance in choosing GROB – and continuing to work closely with GROB today. Tarditi emphasizes: "GROB's technical expertise in the task of machining powertrain components is outstanding. They know every step of the process and deliver stable, highly productive solutions."

In addition, GROB’s structured project management, consistently focused on on-time delivery, quality, and productivity, plays a crucial role. In every phase – from planning through installation to ramp-up – the professionalism and reliability of the GROB team are evident. It is precisely this dependability that makes the difference for Endurance in day-to-day operations.

Another key component of the collaboration is the people involved. Through continuous communication and regular visits to the GROB plant in Mindelheim, a close personal relationship has developed over the years. "People make the difference. With the support of SIMU, and Antonio Goia in particular, we were able to visit GROB regularly and build close relationships with all teams—from sales and project management to the technicians on site," says Tarditi.

A partnership that has grown steadily

Over the past years, the two companies have gotten to know each other better and better. What began as a purely business relationship has gradually developed into a stable partnership. "What was once a classic customer-supplier relationship is now a strategic partnership between equals. We know each other well, can make decisions quickly, and solve problems directly," explains Tarditi. This familiarity not only facilitates daily collaboration, but also accelerates the implementation of new projects.

GROB machines and lines play a fundamental role in Endurance's daily production process. They stand for robust processes, high precision, and maximum availability – qualities that are indispensable in the series production of powertrain components. Especially for new products, such as those for VW, Audi, or Porsche, they were a key success factor in reliably meeting demanding quality and cycle-time requirements.

A special moment for both companies: the 100th GROB machine

A milestone that particularly symbolizes the close cooperation is the installation of the 100th GROB machine at Endurance. For Andrea Tarditi and his team, this number is not only a technical success, but above all a strategic one. It shows how strongly Endurance has been able to position itself with existing and new OEM customers through its partnership with GROB. GROB technology has played a key role in establishing Endurance as a reliable and innovative partner – both for long-standing and newly acquired customers.

Looking to the future: On the way to the 200th machine

Even after this important milestone, the joint journey is far from over. "Our next goal is the 200th machine. I am sure that we will celebrate this success together again," says Tarditi. The close cooperation with GROB will continue to ensure that Endurance can respond flexibly to market requirements and further expand its role in the powertrain sector.

The partnership between Endurance SpA and GROB impressively demonstrates how technological excellence, structured project management, and interpersonal trust lead to sustainable success. Andrea Tarditi sums it up: "What began with initial discussions in 2009 has developed into a long-standing, stable, and valuable collaboration—and will continue to shape us in the years to come."