GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Automotive

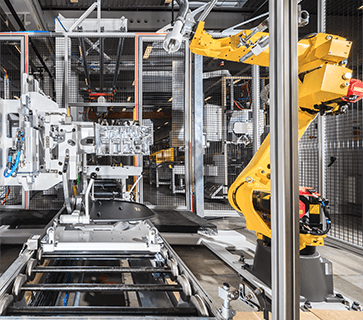

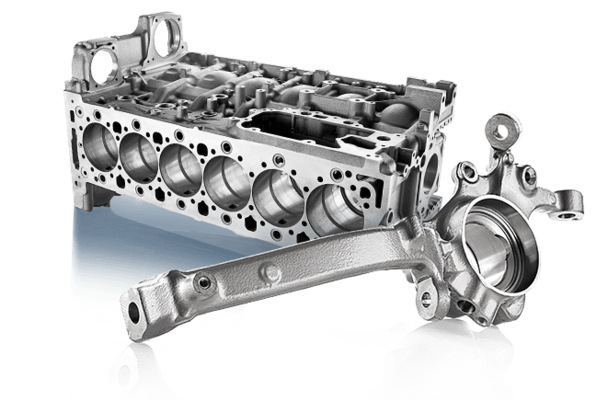

Decades of experience combined with innovative technologies, highly flexible and efficient systems, universal machining centers and assembly lines, make GROB the ideal partner for the automotive industry.

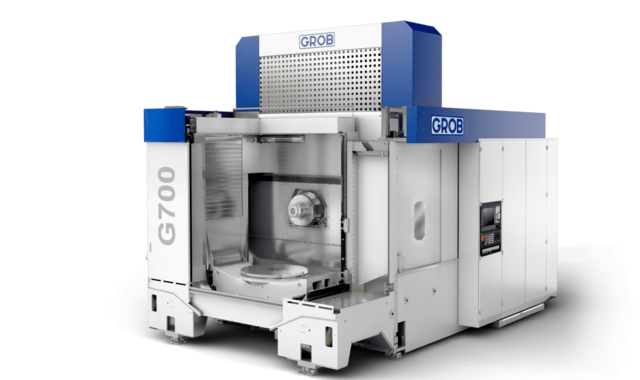

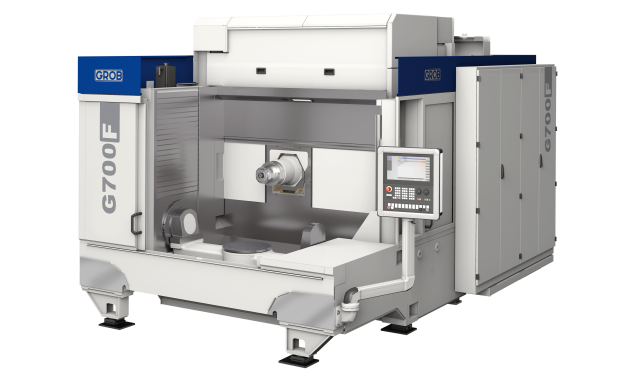

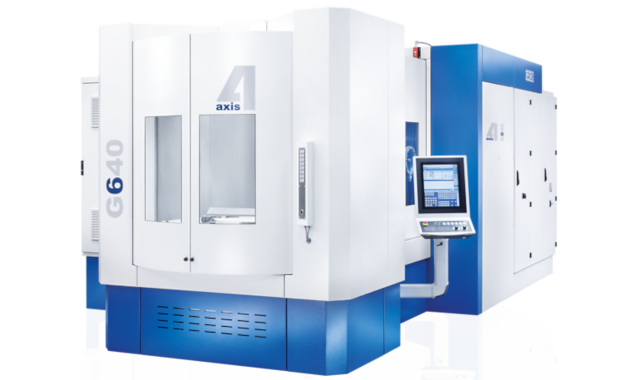

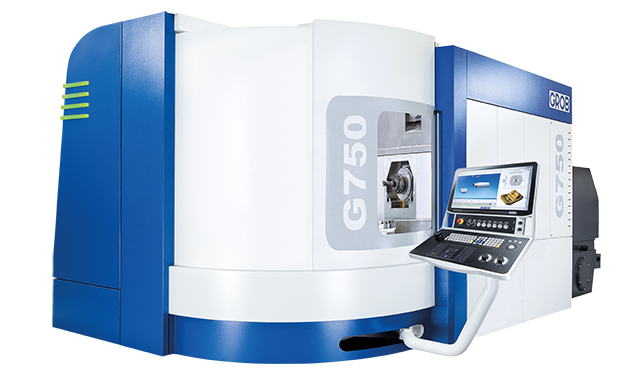

Compact, visible and state-of-the-art: Discover our 5-axis universal machining centers for the optimized milling of a diverse range of materials.

Looking into the future, GROB leads the way in the electromobility sector too. GROB is developing new drive and system concepts to realize powerful solutions for the manufacturing of electric motors and energy storage systems, responding to technological change with individually adapted processes.

GROB has years of experience in the conceptual design of systems for the assembly technology sector. All of our assembly stations and lines are custom-built according to customer-specific needs.

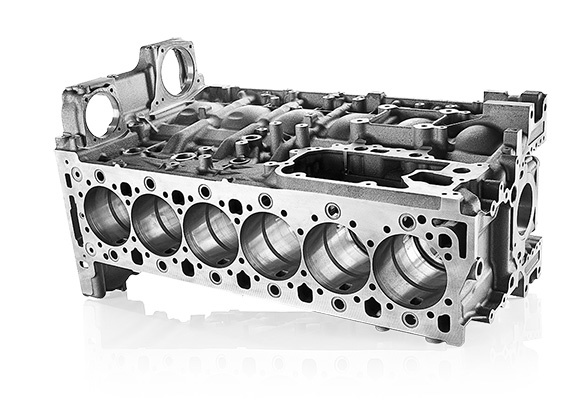

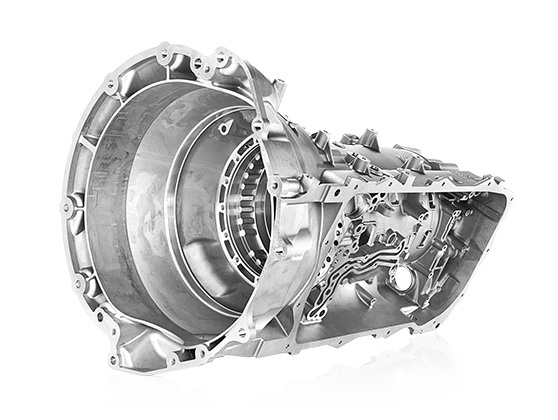

Typical machining operations

| Material | Aluminium alloy |

| Motorized spindle | 12,000 rpm |

| Power/torque | 40 kW/161.4 Nm |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |