GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

You were automatically redirected to our English website.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Ok

Medical technology

From idea to sustainable solution: We accompany you over the entire development of your medical products.

1

Consulting & Support

- Competent consultation, feasibility studies and development of individual solutions

- Processes that can be modeled in compliance with regulations (ISO13485)

2

Application

- Process safety in compliance with highest quality requirements

- Turnkey solutions

- Use of the most state-of-the-art CAD/CAM strategies

3

Parts

- Part-oriented product development for titanium/CoCr alloys that are difficult to machine

- Implementation of the highest process safety, surface quality and accuracy

4

GROB Machine Concept

- Unique horizontal kinematics for efficient simultaneous 5-axis machining

- Multiple clamping and use of short standard tools due to excellent accessibility

- Short compensatory movements

- High dynamic accuracy with simultaneous high rigidity

5

Automation

- Round or linear pallet storage systems for small, medium and large series

- Combined pallet and part handling with the GROB robot cell

- Adaptive machining: Part measurement at the machine with automated tool path generation

- Integration of further processes and technologies

6

Connectivity

- Complete traceability via GROB4Interface

- Optimization of CIP process via GROB4Analyse

- Adaptation to individual data protection guidelines

- Automated documentation with GROB-NET4Industry

No matter whether implants, prostheses or medical instruments: Products for use in medical engineering have to be top notch quality. The dependable and highly precise GROB universal machining centers meet the high requirements of the medical and pharmaceutical sectors and guarantee the reliable manufacture of sensitive parts.

The ideal solution for economic and reliable production of medical devices: The GROB 5-axis universal machines offer medical product manufacturers the best criteria for high surface qualities and precisely manufactured parts.

Typical machining operations

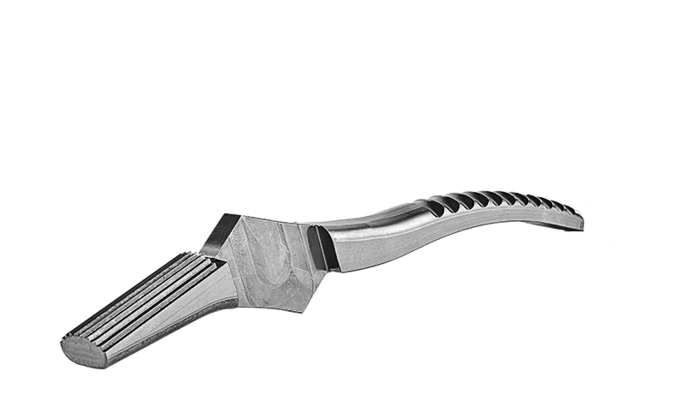

Chisel Holder

| Dimensions of raw material (mm) | Ø 80x250 |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Scalpel holder

| Dimensions of raw material (mm) | 140x10x20 |

| Material | Stainless steel |

| Motorized spindle | 12,000 rpm |

| Power/torque | 52 kW/83 Nm |

Bone forceps

| Dimensions of raw material (mm) | 195x13x25 |

| Material | Stainless steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Bone insert

| Dimensions of raw material (mm) | 50x35x40 |

| Material | Stainless steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Housing cap plasma

| Dimensions of raw material (mm) | Ø 45x60 |

| Material | Stainless steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

GROB Service

Customer service

GROB4Care