Suppliers

Sie wurden automatisch auf unsere englische Website weitergeleitet.

The GROB Supplier Portal

The GROB product portfolio is characterized by the highest quality and maximum reliability. To be able to deliver our machines and technologies in the best quality and on time to our global customers, we need efficient and motivated partners. On this website, you will find all information about the cooperation with our suppliers.

Our Purchasing Department

The Purchasing Department at GROB Group has global presence. The Strategic Purchasing Department at our headquarters in Mindelheim and the Purchasing and Sourcing Teams at our sites in China (Dalian), USA (Bluffton), Brazil (São Paulo) and Italy (Turin) are continuously working on the advancement of the performance of our supplier portfolio as part of a global material group management.

In cooperation with the most efficient suppliers, we ensure the technical and commercial competitiveness of our products. We achieve this by involving and cooperating with our suppliers from an early development phase, by consequently reducing the manufacturing costs and improving the process efficiency.

Product range:

Universal Machining Centers, Machining Technology, Assembly Systems, Electromobility

Employees:

5,600

Production area:

199,000 m2

Product range:

Electromobility

Employees:

100

Production area:

4,800 m2

Product range:

Universal Machining Centers, Machining Technology, Assembly Systems, Electromobility

Employees:

1,200

Production area:

57,400 m2

Product range:

Universal Machining Centers, Machining Technology, Assembly Systems

Employees:

790

Production area:

36,000 m2

Product range:

Universal Machining Centers, Machining Technology, Assembly Systems

Employees:

590

Production area:

45,000 m2

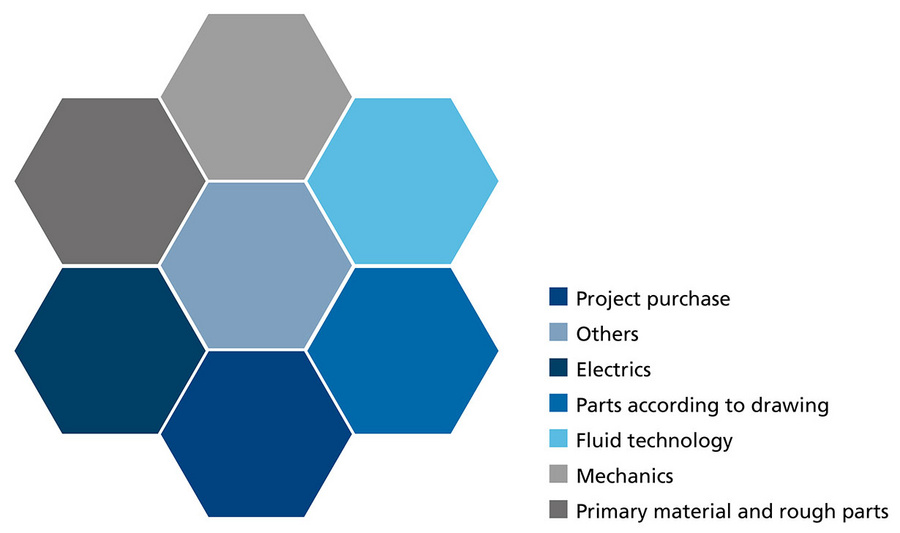

Structure and distribution of the globally used material groups:

Assembly machines

Customer tools

Fire extinguishing systems

Measuring machines

Motorized spindle

Investments Information technology

Packaging material for spare parts and machines

Investments Machines & Systems

Investments Property & Building

Occupational safety

Hardware

Electrical cabinet

Drive components

Installation components

Sensor technology

Single manufactured parts, Finished welding assemblies

Cabinets and enclosures

Single manufactured parts Machining

Single manufactured parts Milling parts

Single manufactured parts Turning parts

General hydraulic components

Valves hydraulics

Pumps hydraulics

Central lubrication devices

Fitting hydraulics

Ball screw

Plain bearing

Guides

Sealing rings

Standard parts/small parts for machines

Welded components

Die-cast aluminum

Sheet metals

GROB profiles

Cuts

Clear conditions of purchase and delivery as well as the compliance with environmental policies, sustainability principles and social standards are important to us. GROB consistently expands its globally leading position as provider of innovative machines and manufacturing technologies for machining technology and electromobility. The high standard we set ourselves is also the standard for the selection of our suppliers: Innovation, technological and commercial competitiveness and the commitment to the continuous advancement are important requirements for a successful cooperation with GROB.

Our General Conditions of Purchase and the Code of Conduct for Business Partners are the basis for our cooperation.

![[Translate to en US:] Downloads](https://www.grobgroup.com/fileadmin/_processed_/4/9/csm_Teaser_Lieferantenportal_Downloads_13d2b27ca0.png)

Downloads

We offer our suppliers the following:

- Technological and innovative leadership ("first to market") in the sector of machining systems and electromobility

- Many years of relationships to all well-known automotive OEMs worldwide as well as to their most important system partners

- Global chances for growth as part of the technological transformation of the automotive powertrain to electromobility

We expect the following from our suppliers:

- Technical and commercial competitiveness

- Development and innovation competence

- Commitment to the continuous improvement of your own products and services as well as cost structures

- Active collaboration on joint measures for product improvement and cost reduction

- Intention for a long-term and collaborative cooperation with GROB

FAQ – Answers to frequently asked questions

Does GROB use a software for strategic supplier management?

Yes, GROB uses a Supplier Relationship Management software which efficiently and transparently controls the supplier management comprehensively from introduction to inquiry, allocation, contract management and supplier development to document management.

Do I stand – in times of the BCC Sourcing Trend – a real chance of a cooperation with GROB as a German supplier?

GROB assesses its suppliers in its entirety. Decisions on the allocation are based on the so-called TCO approach. GROB also assesses the criteria technology, quality and adherence to delivery dates and flexibility aside from the price and the conditions of contract. This gives innovative, small and flexible companies the possibility to come out on top in the international competition despite the factor costs disadvantage.

Do I have an advantage if I use GROB machines in my manufacturing?

GROB approves and supports that you have chosen our machines. If you fulfill all allocation requirements in case of tender, this advantage can be decisive for an award of contract to your company.

I am a special provider for single processes, such as heat or surface treatment, which most of the mechanical engineering companies do not consider as core expertise. Do I stand a chance of contracts with GROB?

It is correct that GROB places special processes externally. However, the complete part purchase is the strategic objective in the area of drawing-bound manufactured parts. Therefore, GROB prioritizes suppliers that offer material purchase and all manufacturing steps from one source and – if necessary – access their own supplier networks.

Which requirements does GROB have on IT, software and formats of technical drawings?

For accessing the SRM (Supplier Relationship Management) you only require an e-mail system and an internet browser. For an efficient and continuous cooperation with GROB, you should use an ERP system which is connected to the GROB ERP (SAP, currently 6.0-EHP8/NW 7.50) via EDI interface. The GROB Engineering Department uses a software by the provider Siemens NX for CAD. For supplier management, GROB exchanges technical documents in common data formats (.dwg, .tif., .step). GROB provides large and sensitive data packages to its suppliers via the web server of the provider OpenDXM GlobalX.

GROB Purchasing Department

E-mail: einkauf@grob.de

![[Translate to en US:] GROB-Weltkarte](https://www.grobgroup.com/fileadmin/_processed_/b/e/csm_Lieferantenportal_Weltkarte_1230_3_27c7e75009.jpg)