GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

You were automatically redirected to our English website.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Ok

Mechanical engineering

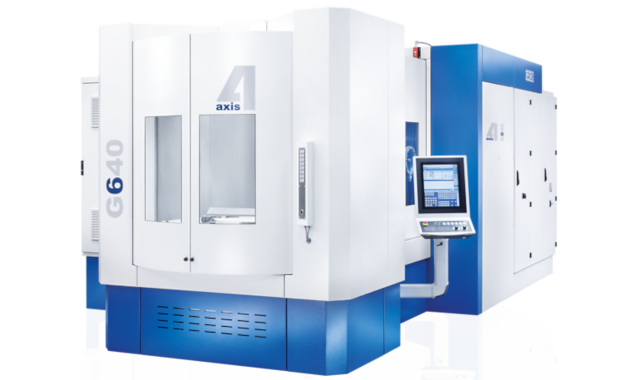

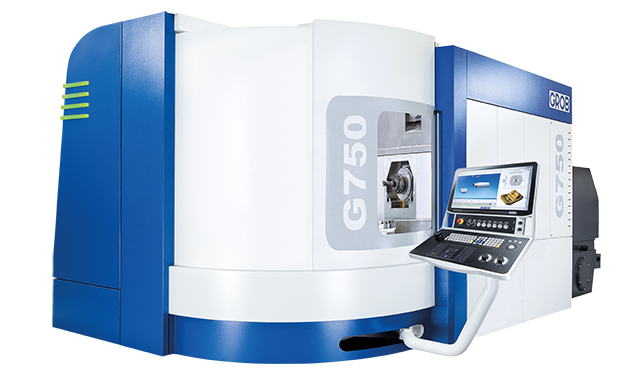

The ideal solution for every challenge: The exclusive concept on which GROB machining centers are based guarantees engineering companies the highest degree of flexibility in their production facility, and also optimized precision in the manufacture of stable components.

For top quality economic production: GROB universal machining centers meet all the requirements of progressive mechanical engineering down to the finest detail and convince through their ability to machine practically any material.

Typical machining operations

Gear wheel

| Dimensions of raw material (mm) | Ø 250x50 |

| Material | Heat treatable steel |

| Motorized spindle | 10,000 rpm |

| Power/torque | 66 kW/340 Nm |

Output carrier

| Dimensions of raw material (mm) | Ø 174x36 |

| Material | C45 |

| Motorized spindle | 12,000 rpm |

| Power/torque | 52 kW/83Nm |

Drill bit

| Dimensions of raw material (mm) | Ø300x350 |

| Material | Steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Connection rod

| Dimensions of raw material (mm) | 160x80x30 |

| Material | Steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Segment of a vice

| Dimensions of raw material (mm) | 415x130x115 |

| Material | Steel |

| Motorized spindle | 9,000 rpm |

| Power/torque | 65 kW/575 Nm |

GROB Service

Customer service

GROB4Care