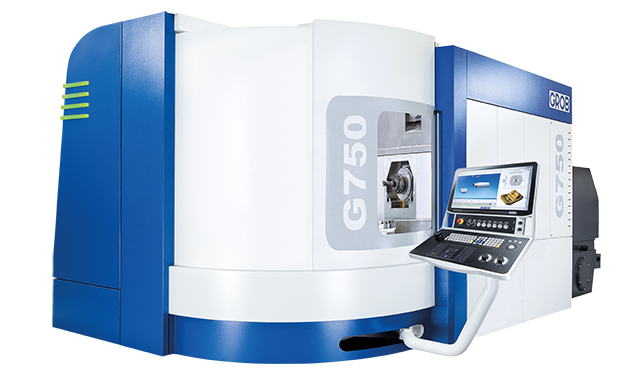

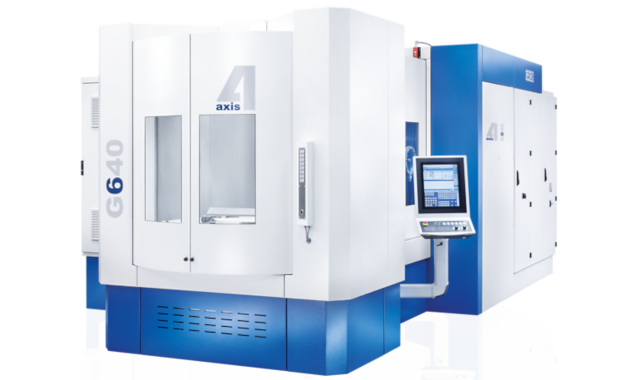

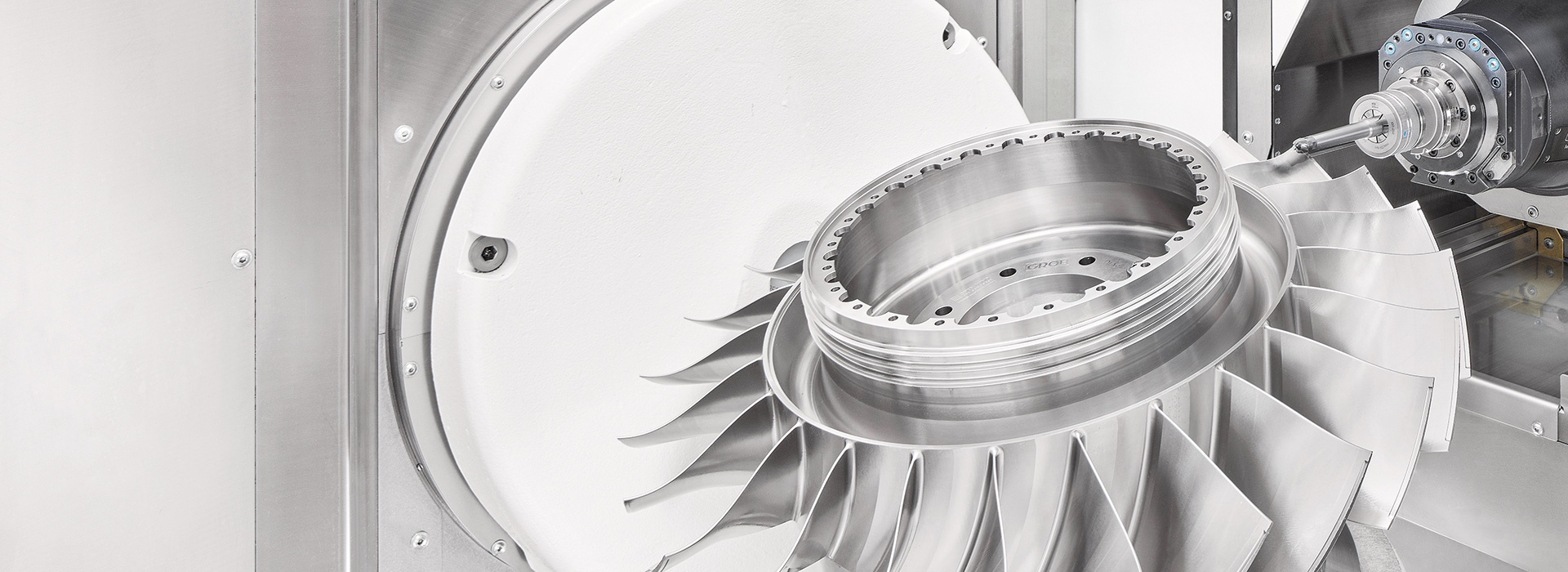

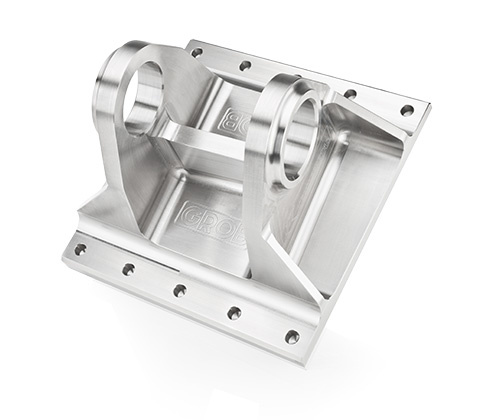

Accuracy is the most important measurement in the aerospace industry. As a partner of the industry, GROB has developed an accuracy package to further improve the accuracy of the parts machined on a GROB. Our accuracy package features:

- Innovative volumetric compensation cycles developed by GROB

- Straightness measurements and compensation taken by laser at your facility

- Thermal stabilization with 12 cooling points: motor spindle, A- and B-axis torque motors, X-, Y- and Z-axis servo drives, X- and Z-axis housing ball screw nut, X-, Y- and Z-axis guide ways, and coolant chiller