- HSK-A/T100, 340 Nm, 10,000 rpm

HKS-A/T63, 206 Nm, 16.000 rpm

HSK-A/T100, 261 Nm, 14.500 rpm

Sie wurden automatisch auf unsere englische Website weitergeleitet.

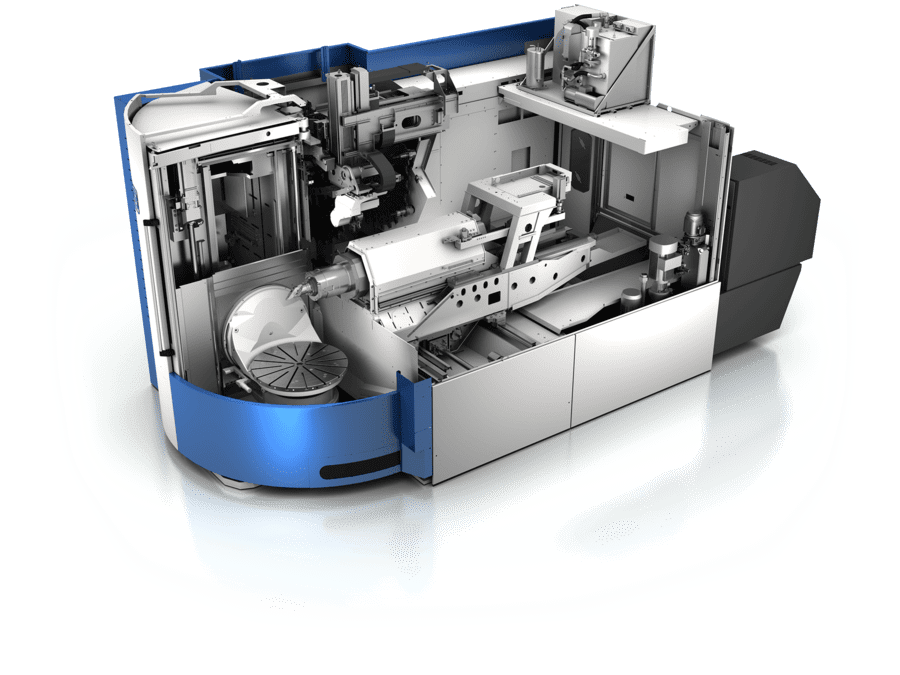

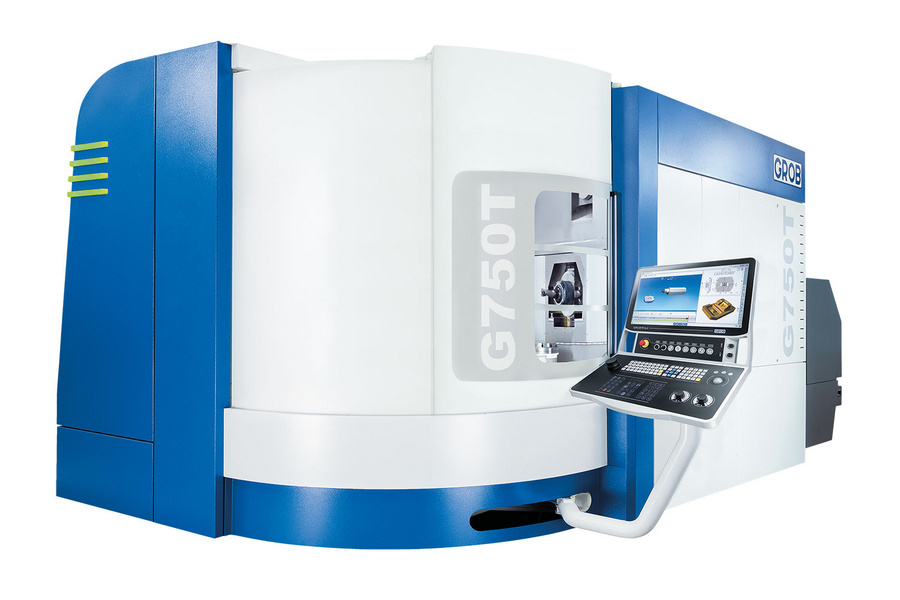

G750T

The horizontal spindle position permits the longest possible Z-travel path and optimum chip fall.

The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), lending the machine considerable stability.

The tunnel concept allows the largest possible component – even in the case of with extremely long tools – to be swiveled and machined within the work area without collision.

Three linear and two rotary axes permit 5-sided machining, 5-axis simultaneous interpolation as well as GROB TRAORI turning. With a swivel range of 230 degrees in the A-axis and 360 degrees in the B-axis, these machines offer the greatest possible positioning flexibility.

Three linear and two rotary axes permit 5-sided simultaneous machining

Almost limitless machining potentials thanks to the largest possible swivel range

Uninterrupted part machining with chip disposal by a slat band conveyor

Intrinsically stiff welded design for optimum machine rigidity

Fast tool change through an intelligent magazine to motorized spindle arrangement

| Dimensions of raw material (mm) | Cast blank |

| Industry | Mechanical engineering |

| Material | GG25 |

| Motorized spindle | 10,000 rpm |

| Dimensions of raw material (mm) | Ø 800x250 |

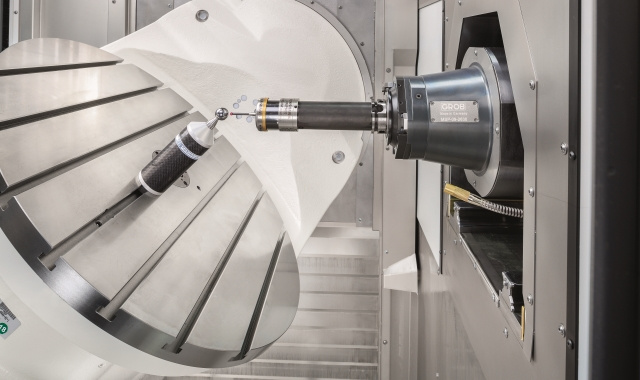

| Industry | Energy technology |

| Material | Chromium-nickel steel |

| Motorized spindle | 10,000 rpm |

| Power/torque | 66 kW/340 Nm |

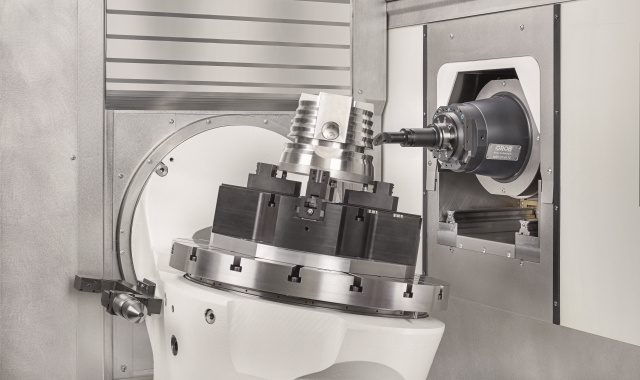

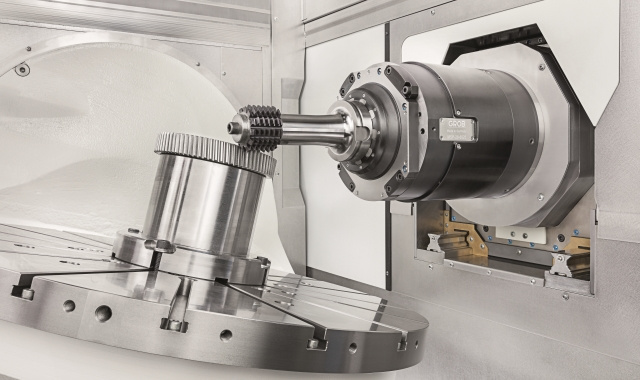

Mill-turn tables

To provide you with the best possible support for meeting the requirements of your mill-turn operations, GROB offers tables, optimized specifically for mill-turn operations, with significantly higher maximum speeds than pure universal milling machining centers.

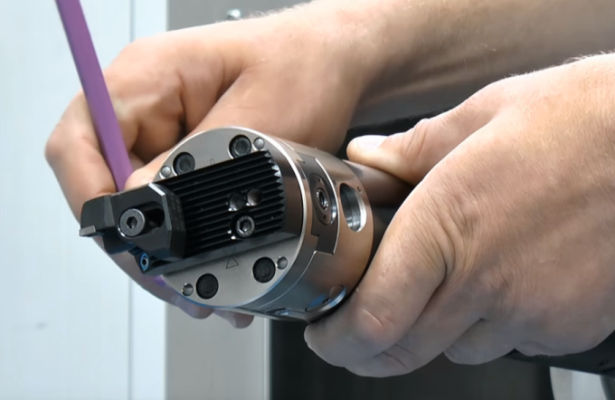

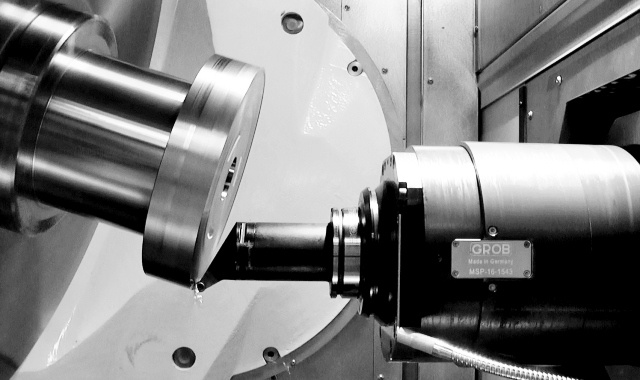

Spindle versions

To optimize the process design of your mill-turn operations, GROB offers mill-turn motorized spindles developed specifically for this purpose.

Tool magazine

GROB tool magazine technology is set apart by fast chip-to-chip times, a smaller space requirement and optimized accessibility. Choose the right solution for you.

- Doube disk-type tool magazine

- Three disk magazine

- Additional tool magazine

Automation solutions

Draw on the experience we have garnered over several decades and benefit from the automation technology we tailor to meet your needs – from solutions with part storage systems to highly flexible manufacturing lines.

Customer-specific automation solution

The tougher requirements in the automation sector call for individual solutions tailored to the customer's specific needs. GROB offers such solutions, from customized part handling through to flexible manufacturing lines with multiple machines and centralized tool supply.

Software options

Use the GROB software solutions to optimize and analyze the machine kinematics of the G750T and minimize deviations down to the finest detail.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

International support

Sites

Directions