- Fast order creation for the production of individual items to large series

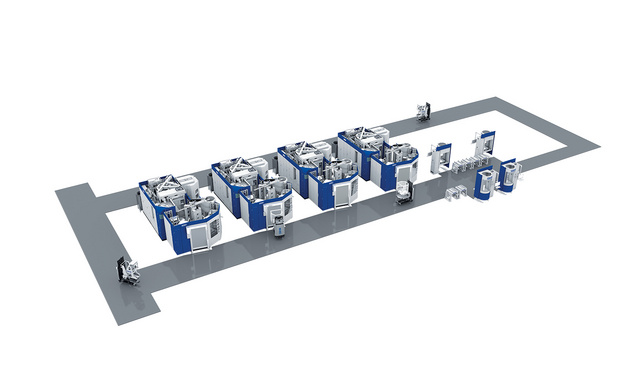

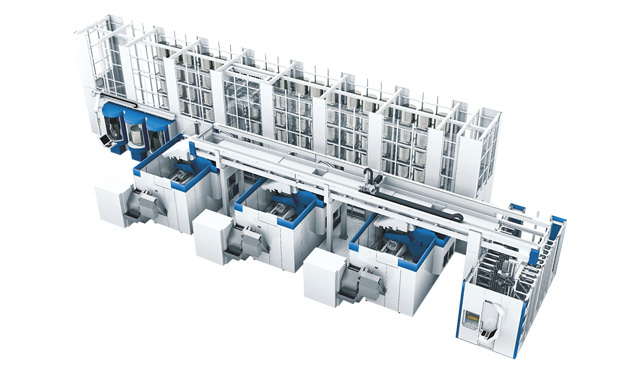

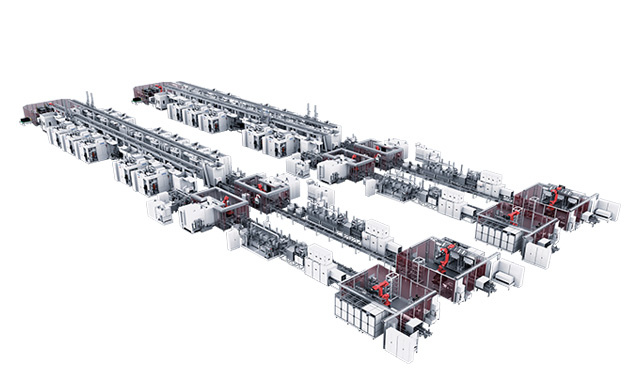

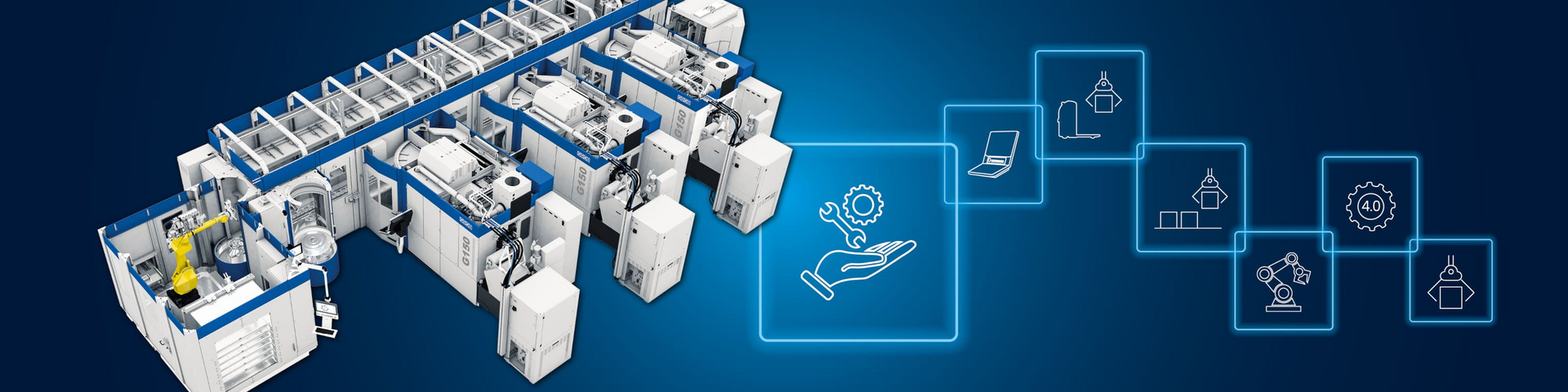

- Clear visualization of the automations and their processes

- Intuitive operation via drag & drop

- Interfaces from a single source

- Unmanned processing of your production orders over several days

- Ability to update quickly when shifting production priorities

![[Translate to en US:] GROB GRC Roboterzelle](https://www.grobgroup.com/fileadmin/_processed_/5/8/csm_Videoteaser_GRC_e758462140.png)