GROB spindle diagnostics is a system that automatically monitors the condition of the motorized spindle. Benefits are a prolonged motorized spindle useful life, reduced tool wear and scheduled maintenance.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

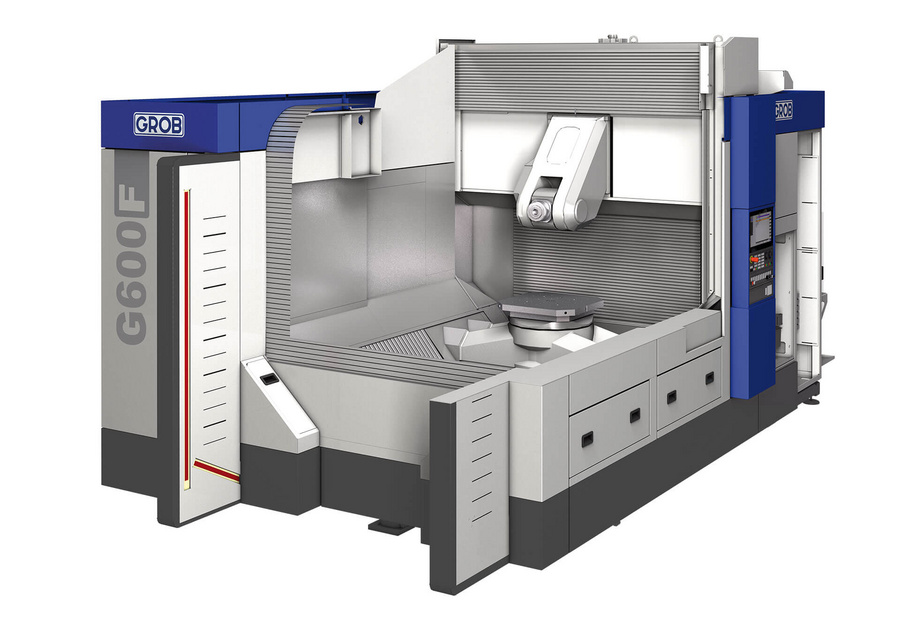

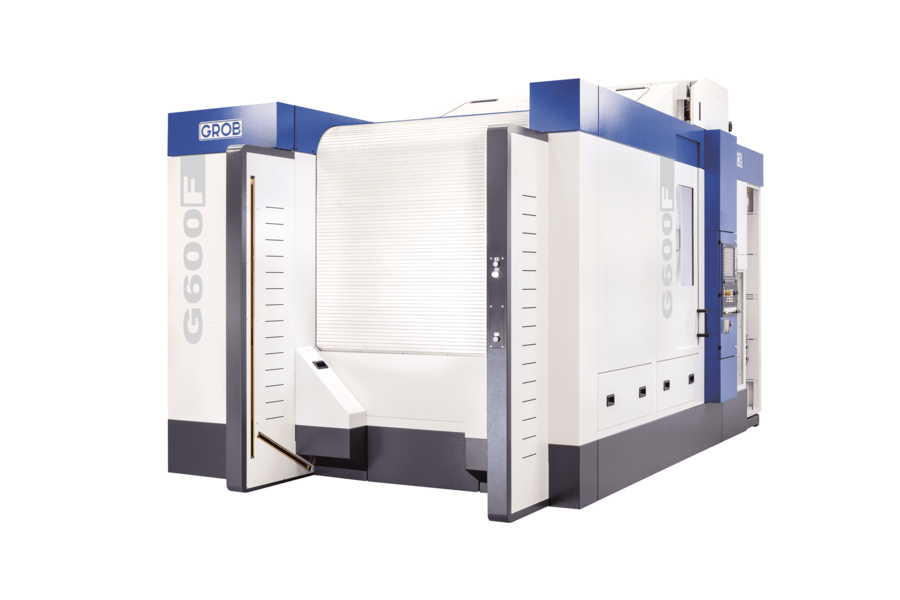

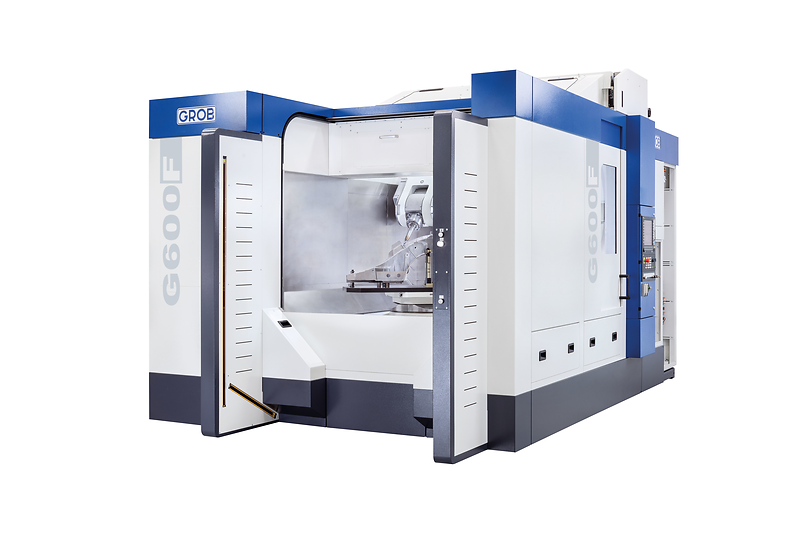

G600F

Version with established AC-kinematics and long travel paths in the X-,Y- and Z-axes

Automatic chip removal to the rear of the machine

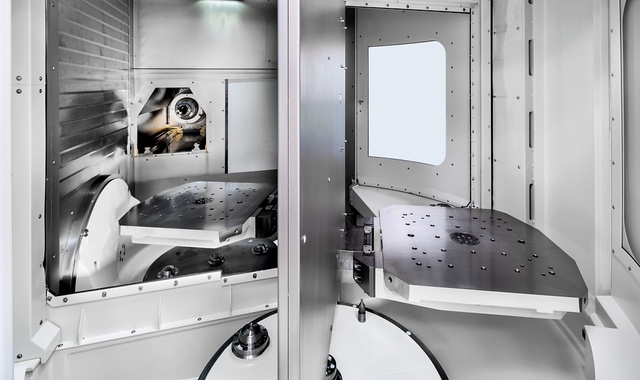

Available with manual or automatic front loading or automatic top loading, and optionally with integrated pallet changer.

Up to 1,750 mm (with restricted Y-travel path) or up to 1,550 mm (no restriction)

Uninterrupted part machining with chip disposal by a scraper-type conveyor

Intrinsically stiff welded design for optimum machine rigidity

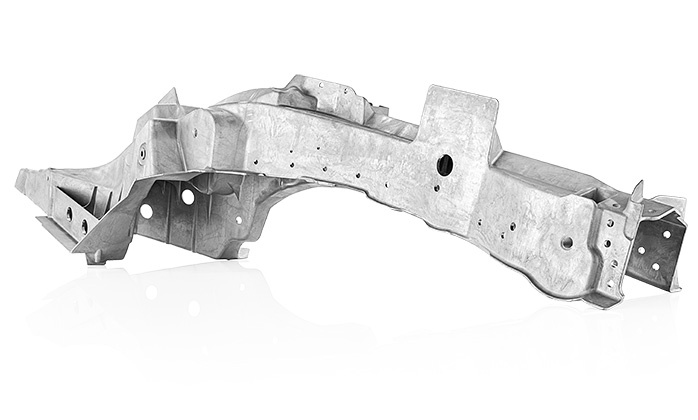

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

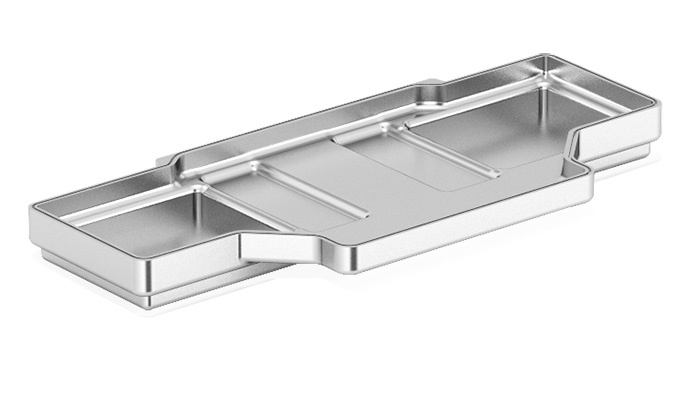

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

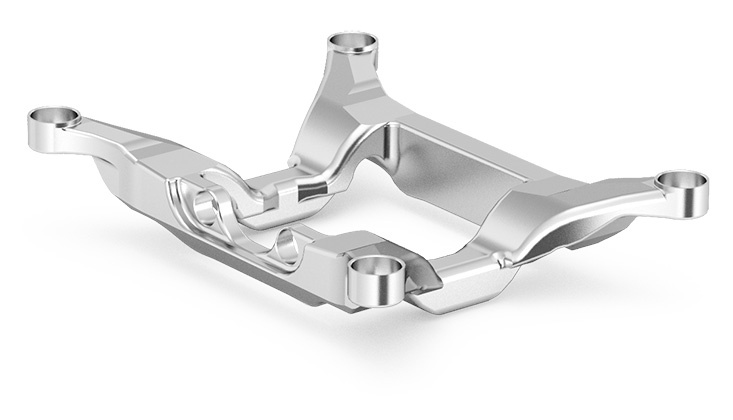

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 29 kW/34.6 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 12,000 rpm |

| Power/torque | 40 kW/161.4 Nm |

| Industry | Automotive |

| Material | Aluminium alloy |

| Motorized spindle | 18,000 rpm |

| Power/torque | 20 kW/26 Nm |

Spindle versions

Besides the broad range of spindles, the motorized spindle designed and manufactured by GROB is the preferred choice for optimized process design. This spindle is perfectly matched to the G600F and has optimized quality features.

- HSK-A63, 34 Nm, 18,000 rpm (standard)

Tool magazine

The single-disk magazine of the G600F achieves fast chip-to-chip times, requires only a small footprint and allows optimum access.

Control systems

Choose between modern and powerful CNC control systems from market leaders for the G600F.

Automation solutions

Draw on the experience we have garnered over several decades and benefit from the automation technology we tailor to meet your needs.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com