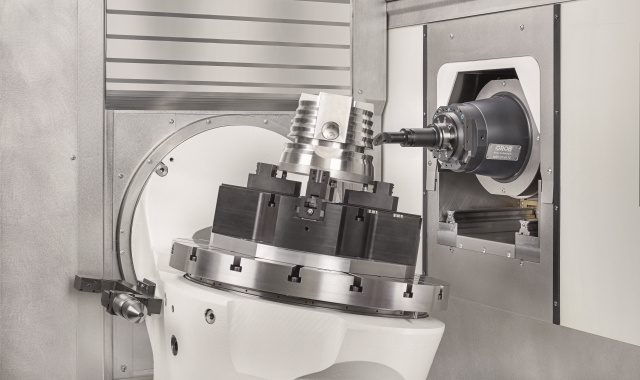

Choose between tilting rotary tables with T-grooves arranged in parallel (standard), as well as tilting rotary tables with pallet clamping system (option). In addition to the standard versions with an A- and B-axis, the "A-axis" (without B-axis) and "B-axis" (without A-axis) options are offered for the G150.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

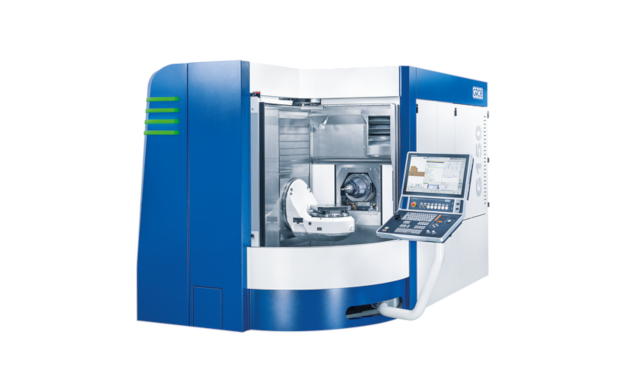

G150

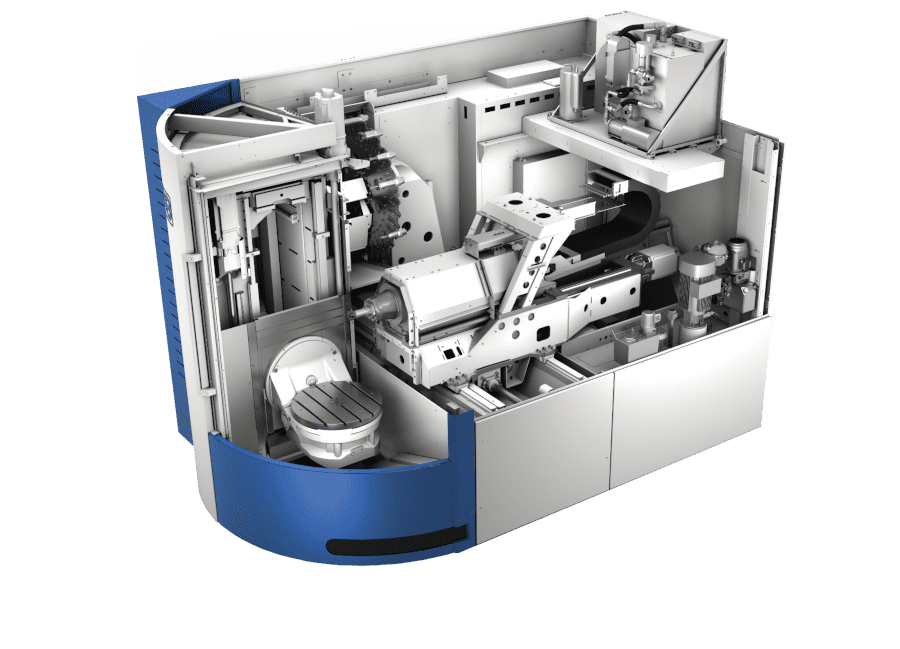

The horizontal spindle position permits the longest possible Z-travel path in the machine class and optimum chip fall.

Three linear and two rotary axes permit 5-sided machining as well as 5-axis simultaneous interpolation.

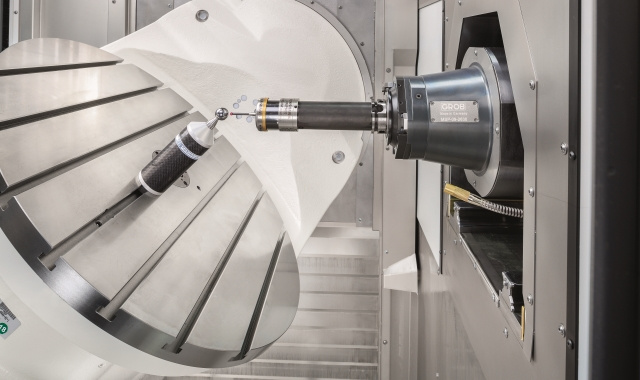

The machine's unique axis arrangement permits overhead machining, offering you an optimum accessibility to the part and almost limitless possibilities for part machining.

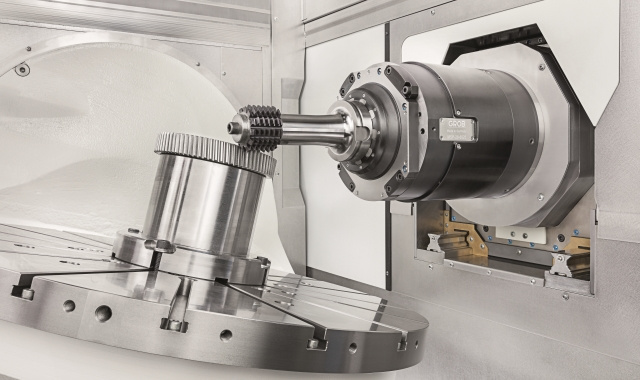

The basis of the drive concept are two symmetrically arranged ball screws and a weight compensation function in the Y-axis. Torque motors in the A- and B-axes ensure dynamic and wear-free machining of parts.

The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), lending the machine considerable stability.

The unique axis arrangement permits an extremely large swivel range of 230° in the A-axis.

The tunnel concept allows the largest possible component – even in the case of with extremely long tools – to be machined within the work area without collision.

REQUEST AN OFFER NOW!

Select your desired specifications for a 5-axis machine from GROB directly in the form and we will send you your personal offer promptly!

Fields marked with * are required.

Active cooling of heat-absorbing components/assemblies

thanks to the optimally positioned bearing close to the operating point

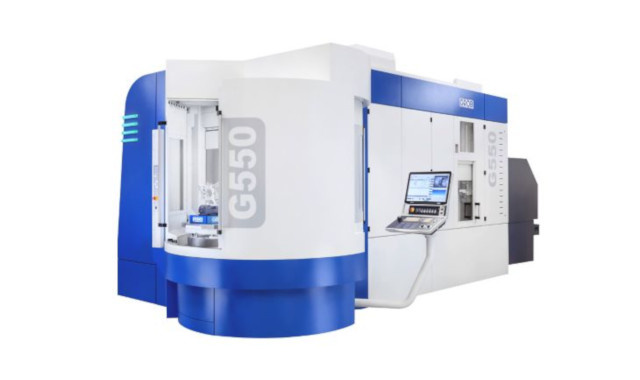

Possibility to choose between SIEMENS or HEIDENHAIN machine control systems

Perfect view of the machining operation through a laminated glass safety screen

with excellent chip fall and reduced thermal load in the part

| Industry | Automotive |

| Material | Aluminium |

| Motorized spindle | 16,000 rpm |

| Power/torque | 25 kW/32 Nm |

| Cutting volume | 20 % |

| Industry | Die and mold industries |

| Material | Aluminium |

| Motorized spindle | 30,000 rpm |

| Power/torque | 40 kW/53 Nm |

| Cutting volume | 65 % |

| Industry | Mechanical engineering |

| Material | C45 |

| Motorized spindle | 12,000 rpm |

| Power/torque | 40 kW/52 Nm |

| Cutting volume | 46 % |

| Industry | Aerospace |

| Material | Aluminium |

| Motorized spindle | 16,000 rpm |

| Power/torque | 25 kW/32 Nm |

| Cutting volume | 90 % |

| Industry | Medical technology |

| Material | Stainless steel |

| Motorized spindle | 21,000 rpm |

| Power/torque | 29 kW/39 Nm |

| Cutting volume | 81 % |

Tilting rotary tables

Various tilting rotary table versions are available for the G150, depending on the requirement. The powerful rotary tables are based on the latest torque motor technology and offer optimized dynamics.

Spindle versions

Besides the broad range of spindles, the motorized spindles designed and produced by GROB itself are the preferred choice for optimized process design.

Tool magazine

- Single disk-type tool magazine

- Double disk-type tool magazine

- Triple disk magazine

Machine control panel

![[Translate to en:] GROB4Pilot](https://www.grobgroup.com/fileadmin/_processed_/7/9/csm_Maschinenbedienpult_GROB4Pilot1_3b63286a27.png)

The innovative GROB4Pilot machine control panel offers the machine operator a convenient working environment on the machine through a multi-functional user interface. The entire production process – from the CAD model through to the NC simulation – is now digitally mapped on the GROB4Pilot control system itself.

| Features: | Advantages: |

|

|

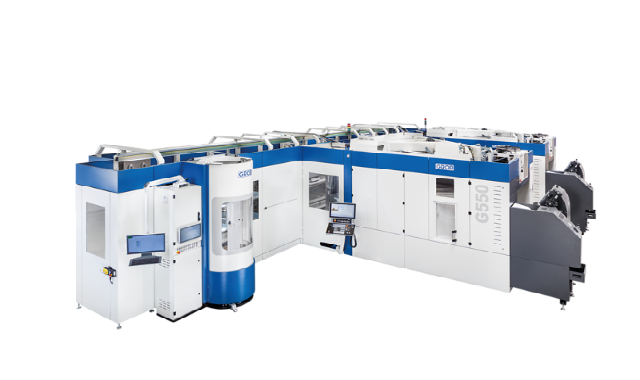

Automation solutions

For its entire product range, GROB offers top-quality components of its own manufacture for partially to fully automated production.

Software options

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com