The right concept for your sector

Sie wurden automatisch auf unsere englische Website weitergeleitet.

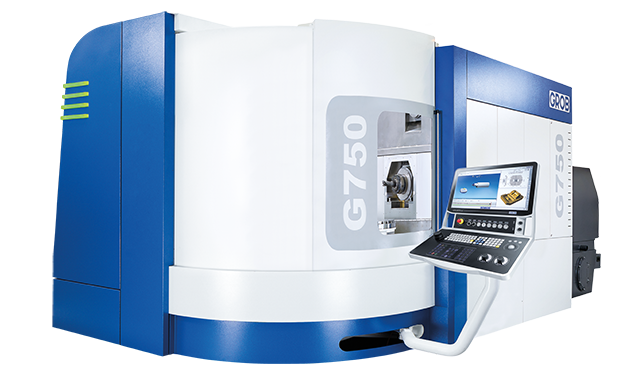

Milling centers

Universal machining centers for optimized milling results

GROB machining centers offer you almost limitless possibilities for machining parts from the most diverse materials and adapt to your requirements down to the finest detail. The compact design, large swivel range and horizontal spindle position are just some of the outstanding machine features that make GROB the ideal partner for your manufacturing facility. The new access-series rounds out the product range of GROB universal machining centers, offering ideal entry versions to the company's unique technology.

REQUEST AN OFFER NOW!

Select your desired specifications for a 5-axis machine from GROB directly in the form and we will send you your personal offer promptly!

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com