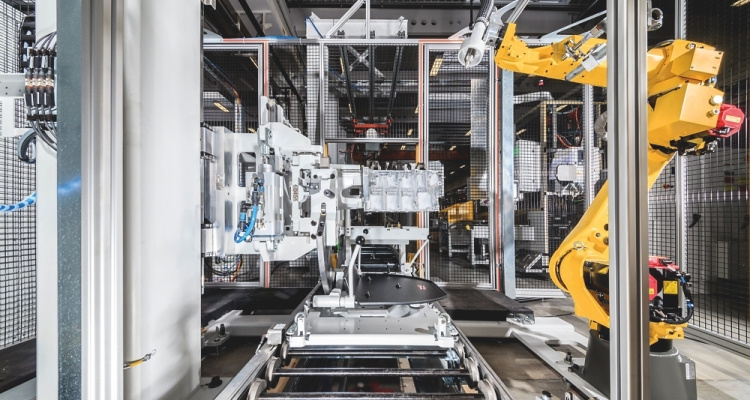

Fully automated GROB stations have an automated assembly sequence designed specifically for high output and complex processes.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Assembly stations

On the basis of a successful assembly concept, GROB manufactures standardized assembly stations, which can be linked by a modular principle to form complete systems with appropriate cycle times. Depending on application and ultimate objective, the choice between fully automated, partially automated and manual stations offers the optimum solution for sophisticated production. Working closely with its customers, GROB develops assembly solutions to suit their needs. GROB combines modular stations to create an individual and highly flexible assembly line.

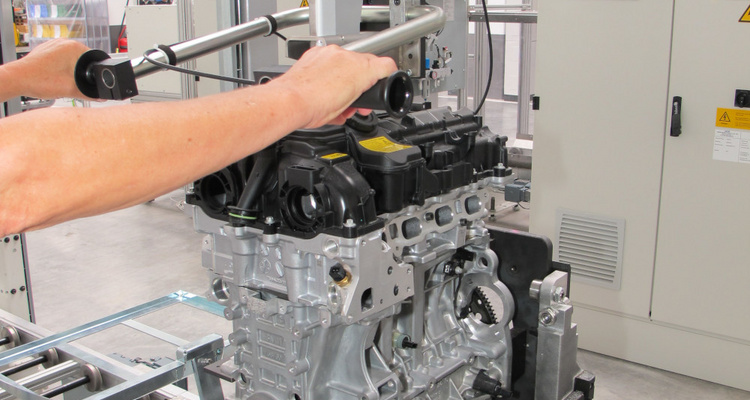

In partially automated GROB stations, the part feed and assembly processes are manual or partially automated. This guarantees optimum synchronization between the operators and the assembly line.

Manual GROB stations are the ideal solution for tasks that are difficult to automate, such as changing scopes, or wherever high flexibility and low investment are needed.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com