In assembly technology, GROB has an extensive range of automation system conveyors, lift and rotary tables, part-specific pallet systems, as well as feed and storage systems. All the components can be combined in any configuration and guarantee an optimum assembly sequence.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

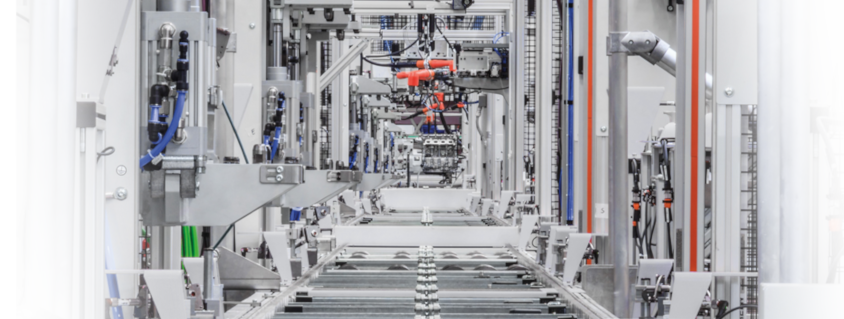

Assembly lines

From a partially automated to a fully automated system, GROB assembly lines are custom-build to meet individual customer needs. GROB lines are guaranteed to accomplish demanding assembly tasks.

Backed by years of experience, the GROB concept has proved its worth, especially in the planning and manufacturing of highly complex assembly lines. GROB has engineered assembly lines for cylinder heads, basic engines, and both automatic and manual transmissions.

GROB's assembly technology allows parts to be transported in a variable automated manner. They can be moved either by a conveyor or a part carrier. Thanks to its customized design, the carrier conveys not only parts but also components for assembly in the individual stations.

GROB is one of the few manufacturers to deliver machining systems with interconnected assembly technology from a single source. The overall concept comprises planning, simulation, commissioning and a trial run in the plant to guarantee the best possible quality and output.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com