GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com

You were automatically redirected to our English website.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Ok

Energy technology

The recovery and use of diverse energy sources is changing and advancing all the time. GROB's innovative machines offer companies in the energy technology sector sophisticated and future-proof solutions for machining complex and highly stable parts from practically any material.

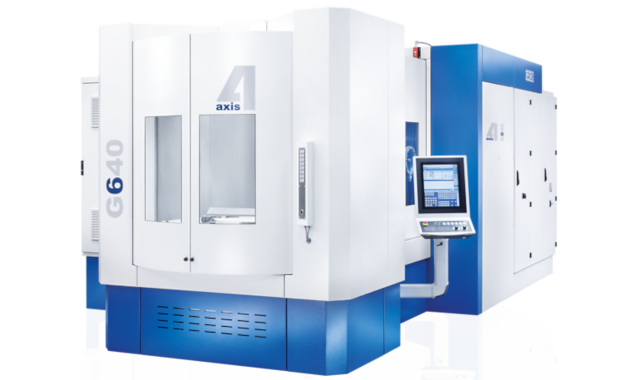

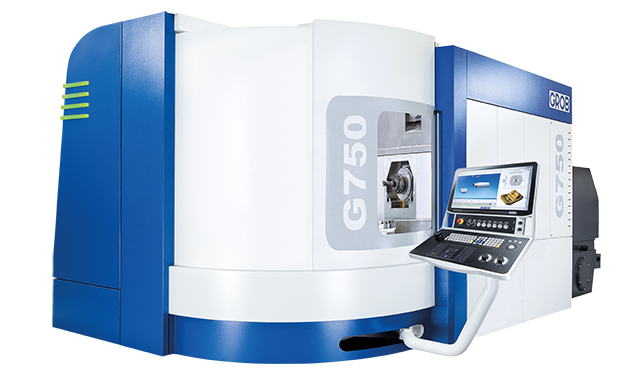

The GROB universal machining centers guarantee precise machining results with outstanding machine quality. As milling or mill-turn versions in various sizes, our universal machines are able to machine parts in any angular position and are therefore the ideal solution for energy technology companies.

Typical machining operations

Centrifugal compressor

| Dimensions of raw material (mm) | Ø 500x165 |

| Material | Stainless steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

Gas turbine blade

| Dimensions of raw material (mm) | 70x50x200 |

| Material | Stainless steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

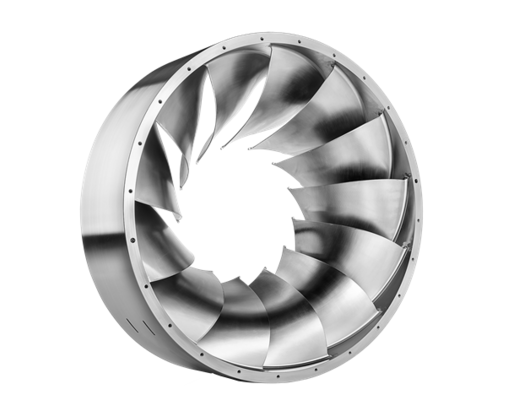

Francis turbine wheel

| Dimensions of raw material (mm) | Ø 800x250 |

| Material | Chromium-nickel steel |

| Motorized spindle | 10,000 rpm |

| Power/torque | 66 kW/340 Nm |

GROB Service

Customer service

GROB4Care