The full GROB package

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Technological

milestones

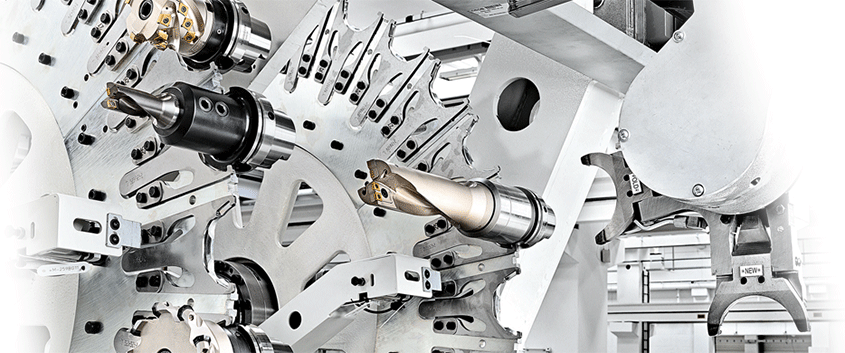

Impressive technology

Since the production of the first thread milling machine in 1933, GROB has been a pioneer in the construction of innovative and high-quality machine tools. And to stay at the top of our game, our goal is continuous further development. See our innovative strength for yourself and discover the high points of our technical developments.

- Introduction of the new G900 series for machining extruded profiles, mega and giga castings

- Presentation of the GROB driverless transport system (GMR)

- Presentation of the first GROB Liquid Metal Printing Machine (GMP300) from the additive manufacturing sector

- Plant concept development for cell assembly of battery cells

- Introduction of the second plant generation for battery module assembly

- Delivery of the first large-scale plant for automatic production of wave-wound stators

- Manz, GROB-WERKE and Dürr enter into unique European cooperation in the field of production technology for Li-ion batteries

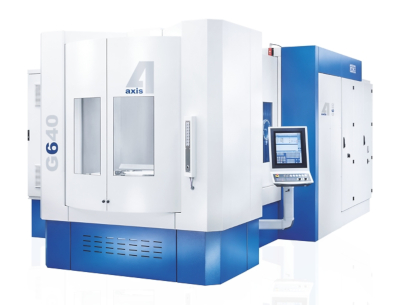

- Introduction of the new 4-axis milling centers with the machine variants G440, G640 and G840

- Presentation of the universal machining center G750 – Generation 2

- Expansion of the automation solutions by the rotary and linear pallet storage systems PSS-R1800 and PSS-L1800, the Vision robot cell (GRC-V) and the pallet tower storage system (PSS-T300)

- Introduction of development stage 7 of the G-modules G300 and G500 from the system section

- Presentation of the first battery cell production plant with Z-folding

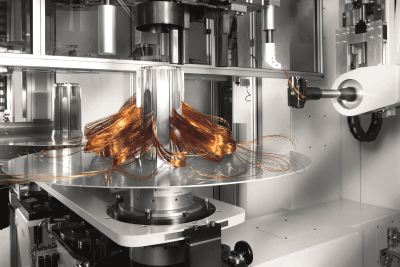

- Presentation and delivery of larger quantities of needle winding machines for fully automatic winding of rotors

- Further development of the series machines for Hairpin 3.0

- Revision of the entire line concept to integrate Hairpin 2.0

- Introduction of the G150 universal machining center as the smallest GROB 5-axis universal machining center

- Expansion of the F-series by the two-spindle machine variant G720F for machining two frame structure parts in parallel

- Presentation of development stage 7 of the modular machining centers G300 and G500 from the system business

- Expansion of the automation solutions range by the GROB robot cell (GRC) and the GROB rotary pallet storage system light (PSS-R light)

- Presentation of the first battery cell production plant with laminator

- Delivery of the first large-scale system for fully automatic trickling of stators

- Expansion of the product portfolio of system concepts to include the production of hybrid and electric drives as well as the assembly of battery modules and fuel cells

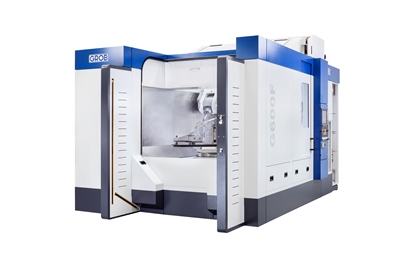

- Launch of a convincingly smart and economic new access-series with universal machining centers G350a and G550a

- Addition to the F-series machining center platform with the introduction of the G700F

- Development of a linear pallet storage automation system (PSS-L) for universal machining centers

- Development of further G-module options

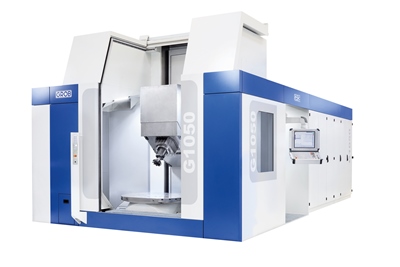

- Expansion of the universal machining center range by the large machining center G1050

Introduction of the new F-series for machining frame structure parts in the form of G500F, G520F and G600F machining centers

- Entry into the electromobility sector

- Development of the two-spindle machining center with pallet changer

- Development of a thermal spraying machine for cylinder blocks

- Introduction of a new generation of system machines and universal machining centers

- Development and introduction of the G800, a large machining center with 6-axis kinematics

- Development of a modular assembly concept

- Presentation of GROB-NET4Industry as an advancement of G-Net at the EMO trade fair in Milan

- Introduction of the rotary pallet storage system PSS-R5/10/13

Introduction of GROB-NET4Industry, the newly developed production software for network and digitalizing production processes

- Presentation of the 5-axis universal machining center G750 and a highly-dynamic linear gantry at the EMO trade fair in Hanover

- Development of a special-purpose milling machine/drilling jig for machining G-module series cross slides

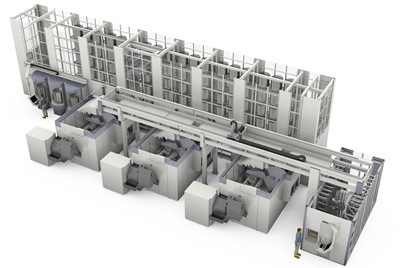

New development of a flexible manufacturing line for large components, consisting of four portal machining centers with HV swivel head in the C-axis and in the Y-slide for the in-house production of large components

- Presentation of the G550T, a 5-axis milling and turning machining center with electromechanical pallet changer and a manufacturing line with compact automation system, part pusher and gantry, at the EMO trade fair in Hanover

- Development of a flexibly linked manufacturing line for the in-house production of medium-sized components with G-modules

- Presentation of the first non-hydraulic machining center at the AMB trade fair in Stuttgart

- Development of a manufacturing cell for machining beds for in-house production

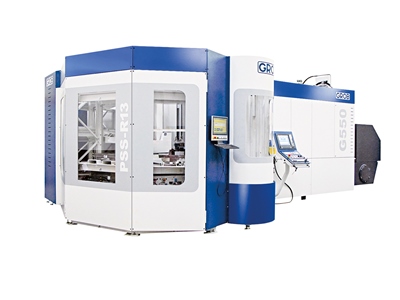

Presentation of the 5-axis universal machining center G550 to the trade press

Delivery of the thousandth G-module in just under three years after being launched on the market

Presentation of the innovative 5-axis universal machining center G350 at the EMO trade fair in Hanover

Introduction of modular machining centers in the form of the G-series

Delivery of the world's first flexible manufacturing line with minimum quantity lubrication for the complete, large-scale machining of transmission cases

- Introduction of the machining center series with high-production types BZ530 and BZ540 as two-spindle mandrel machines for automatic part loading and unloading, especially suitable for the increasingly popular flexible production machines

- Large T-types expanded by the BZ1250 and the BZ1600 with pallet dimensions of up to 1,600 x 1,800 mm

- Development of the BZ510, the first universal machining center for large consumer retailers

- Introduction of the first two-spindle machining center BZ520 in the form of a mandrel machine suitable for wet and dry machining

Production of the first GROB machining center with linear motor drives (BZ600L), designed for high speeds and fast acceleration along the linear axes

Introduction of the BZ40CS, a highly-dynamic and compact machining center with stand-alone capability, either as part of manufacturing lines or as a 3-axis CNC module for transfer lines

Development and production of the first highly-dynamic and precisely-positioning robots as gantry version

Start of development for the machining center series

Delivery of the first automatic assembly line for passenger car oil pumps

Production of the first GROB machining center for vehicle axle casings

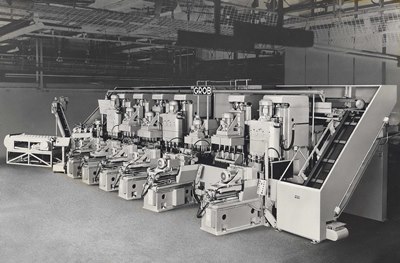

Completion of the first transfer line for machining truck front axles to be completely engineered, constructed and assembled in the Mindelheim plant

- Production of the first transfer line, a 13-pass, 10-station machine for refrigerator compressor housings

- Production of the first GROB special-purpose machine with NC control for a flexible transfer stroke modified to suit the part type concerned

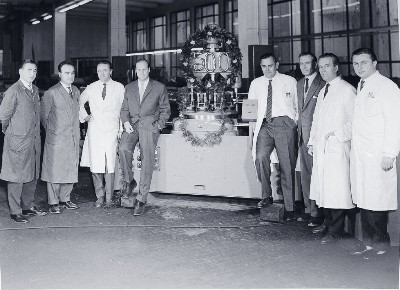

Delivery of GROB special-purpose machine number 500 from the Munich plant, a 4-pass, 8-station planetary table machine for pressure valve seats for METAL EXPORT (Poland)

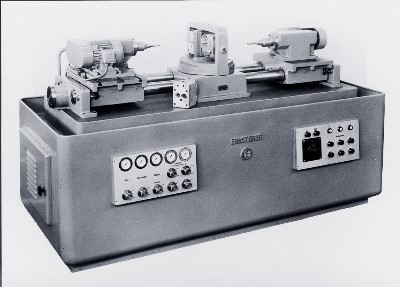

Engineering and production of rotary tables, translation tables and precision lathes

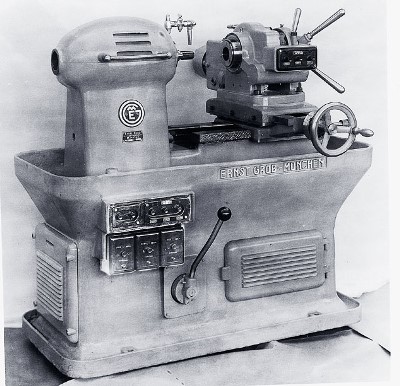

Start of production for special-purpose machine tools, such as parting and centering machines

Process development to chipless metal forming leads to the construction of thread rolling machines

Production of the first thread milling machine and start of machine tool construction