The advantages of the continuous hairpin lie in the economic feasibility of high numbers of slots with large inside diameters. With this technology, the prefabricated wire mat is inserted into the stator, making small wire cross-sections easily manageable and eliminating the need for complex circuitry. GROB uses flat winding for continuous hairpin assembly.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

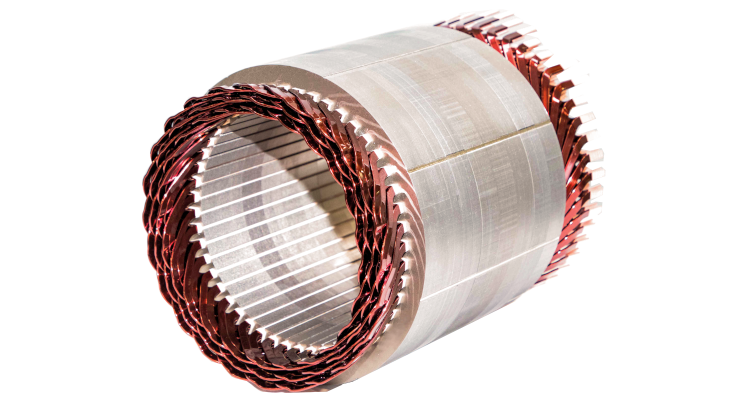

Electric motors and E-machines

Together with you, we realize the drives of the future: GROB develops and builds machines and systems for the large-scale manufacture of stators and rotors. At our sites in Mindelheim and Turin, we are working on the various winding technologies for round and rectangular wires – depending on drive and motor size. The product range spans from stand-alone, semi-automatic machines through to fully automated turn-key systems for our customers from the automotive industry. Competence, quality and speed are the basis of our customized solutions and future developments.

GROB supports its customers in each phase of the product development process – from simultaneous engineering and the construction of the first prototypes to the series production and the appropriate assembly line, tailored to your requirements and needs.

Services for the e-machine sector

- E-motor and e-axis assembly

Fully automated turn-key systems, tailored to your specific needs

- Stator assembly

Systems for the stator production with different winding technologies

- Rotor assembly

Systems for the rotor production with proven technology

An innovative bending concept enables very high flexibility and a wide range of variants. By using preformed, open coil segments made of conductors with a rectangular cross-section (so-called hairpins) and the high degree of automation, this technology allows high-quality stators with the highest filling ratios to be manufactured.

The advantage of the coil-inserting technology lies in a proven process. It is used in electric motors for all size and performance classes, from consumer goods to the automotive industry. GROB offers two methods for manufacturing stators using the insertion technique:

- Flyer winding

- Template-based winding

Needle winding technology is a complex process for applying round wire for e.g. externally excited rotors. The advantages of this process are, on the one hand, the consistent performance of the rotor over its entire service life and, on the other hand, the possibility of control via copper packets.

Want to know more?