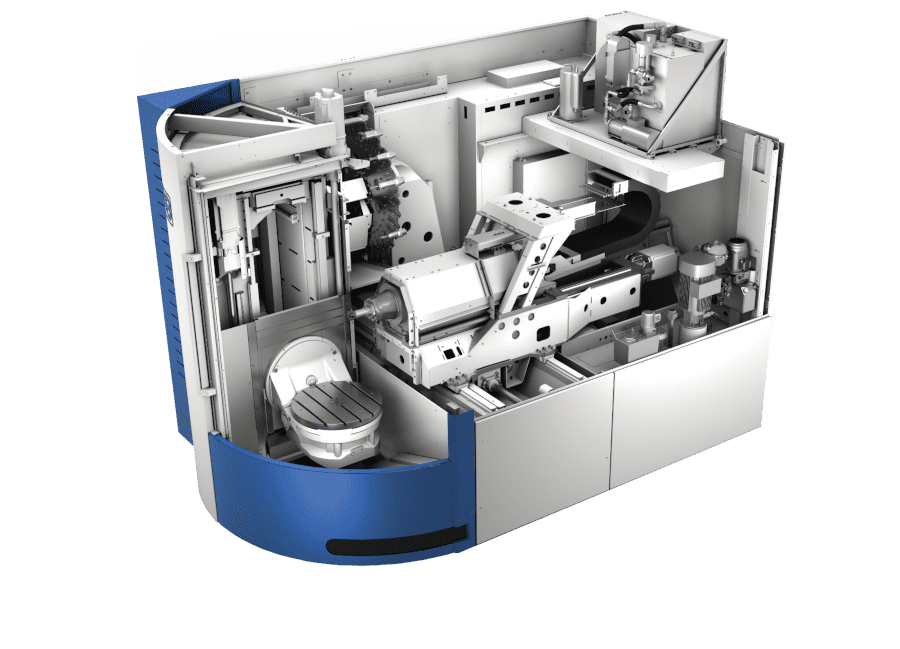

- Optimally designed machining point (TCP) for extreme rigidity

- Longest Z-travel path in this machine class

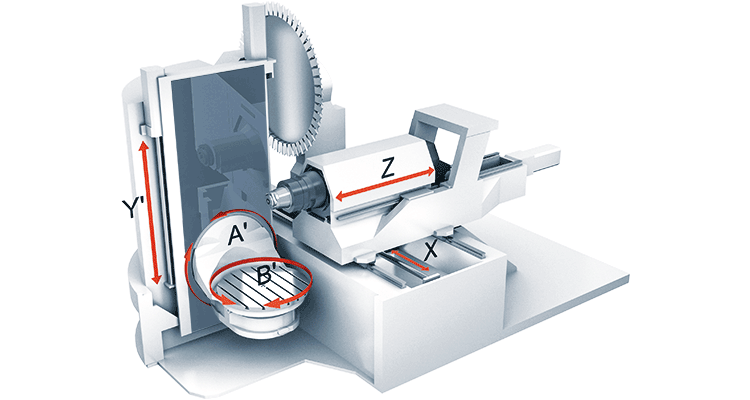

- Extremely large swivel range of 230° in the A-axis

- Largest possible part in the work area can be machined with maximum tool length

Sie wurden automatisch auf unsere englische Website weitergeleitet.

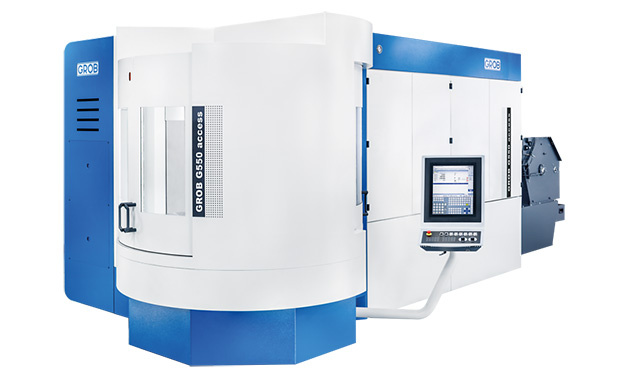

G350a

The horizontal spindle position permits the longest possible Z-travel path and optimum chip fall.

The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), lending the machine considerable stability.

The tunnel concept allows the largest possible part to be swiveled and machined within the work area without collision – even in the case of machining with extremely long tools.

Three linear and two rotary axes permit 5-sided machining, as well as 5-axis simultaneous interpolation, with a swivel range of 230 degrees in the A-axis and 360 degrees in the B-axis.

REQUEST AN OFFER NOW!

Select your desired specifications for a 5-axis machine from GROB directly in the form and we will send you your personal offer promptly!

Fields marked with * are required.

with optimally positioned bearing close to the operating point

with excellent chip fall and reduced thermal load in the part

Active cooling of heat-absorbing components/ assemblies

thanks to compact machine concept

of the machining operation through a laminated glass safety screen

Possibility to choose between SIEMENS and HEIDENHAIN machine control systems

| Dimensions of raw material (mm) | Ø 174x36 |

| Industry | Mechanical engineering |

| Material | C45 |

| Motorized spindle | 12,000 rpm |

| Power/torque | 52 kW/83 Nm |

| Dimensions of raw material (mm) | 160x80x30 |

| Industry | Mechanical engineering |

| Material | Steel |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/206 Nm |

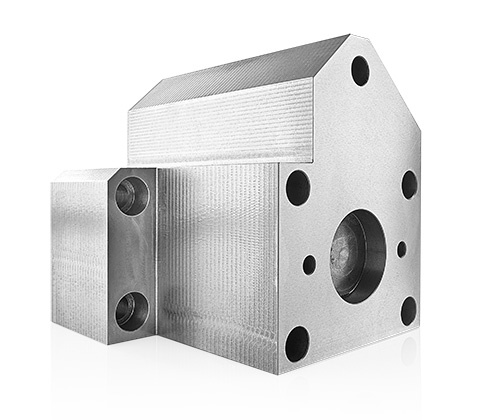

| Dimensions of raw material (mm) | 150x150x100 |

| Industry | Mechanical engineering |

| Material | 1.1191 / CK45 |

| Motorized spindle | 16,000 rpm |

| Power/torque | 32 kW/205 Nm |

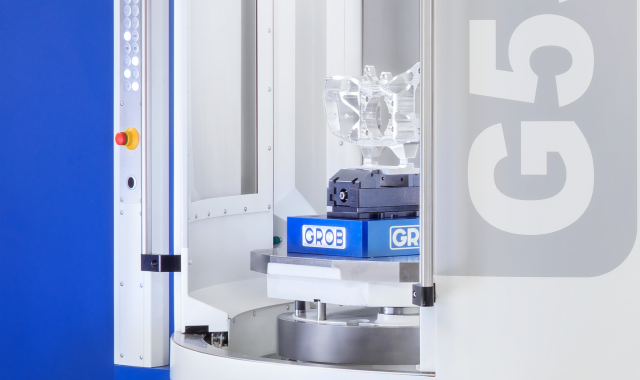

Automation solutions

Axis arrangement

Three linear and two rotary axes permit 5-sided machining, as well as 5-axis simultaneous interpolation.

Spindle versions

Besides the broad range of spindles, the motorized spindles designed and produced by GROB itself are the preferred choice for optimized process design. These are optimally matched to the G350a and have optimized quality features.

Available option packages

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com