The "Gallardo", the most popular mo- del from Italian sports car manufactu- rer Lamborghini, is already considered a classic among sports car enthusiasts – especially the first series with a 10-cy- linder engine and 5.0-liter displace- ment. Many Lamborghini fans believe that this model sounds richer and more elegant than the engines used later on. Unfortunately for them, however, this engine is virtually unavailable now.

Philipp Kaess, a well-known car mechanic, YouTuber, and TV presenter, and Andre Wojtkowski, owner of Subi-Performance, have therefore launched an ambitious project: the complete remanufacturing of an engine block – not from cast aluminum like the original, but based on a significantly more stable billet block.

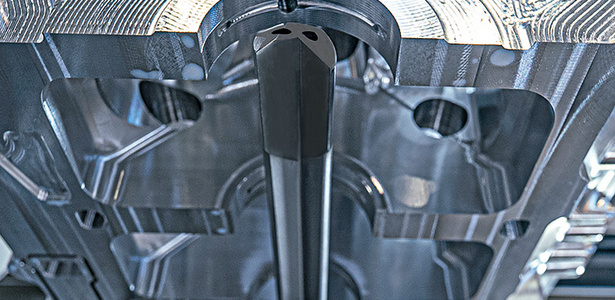

Similar to the aluminum structural com- ponents commonly used in aviation, such a block is machined from solid material in order to achieve the desired strength. The use of a homogeneous and solid block prevents cavities and unwanted in- clusions, and the properties of the raw material can be specifically adjusted by heat treatment. The raw material used is a high-strength aluminum alloy 3.4365 (AW-7075). The design is based on the original engine, but has been modified and optimized in terms of the desired increase in performance, the more stable design, and the resulting changes in static, dynamic, and thermal properties.

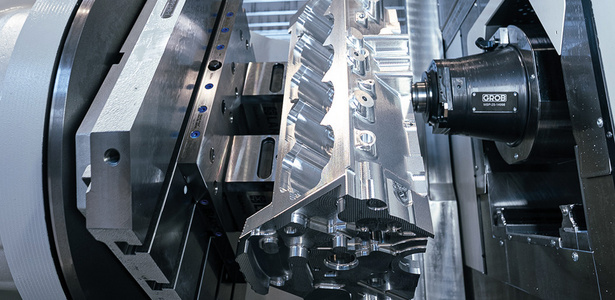

In order to turn raw material and a CAD model into a 2,000 hp engine, reliable and highly accurate machining is required. Subi-Performance therefore uses the Grob G550, a powerful, flexible, and highly precise 5-axis universal machining center with modern controls and a large working area. Another key advantage is the horizontal spindle position of the universal machine, which means that chips do not remain on the component during milling and drilling but fall directly into the chip conveyor. This is particularly important for roughing, as 85% of the raw part volume is removed during the production of the billet block. The ho- rizontal spindle allows the use and au- tomated changing of very long tools, which proves to be an immense advan- tage in view of the required deep ho- les in four different diameters. Combi- ned with a generous cooling lubricant supply of up to 80 bar, the conditions for reliable chip removal are also met.

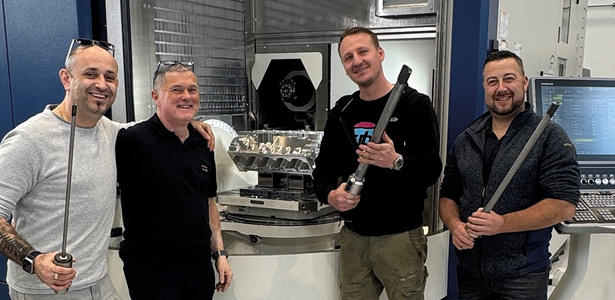

To implement the project, Andre Wojtkowski is relying on the expertise of three experienced specialists: milling and CAM specialist Kevin Witt, managing director of SAW Technologie GmbH; Markus Huber, application engineer at Grob-Werke GmbH & Co. KG; and, for deep hole drilling, Armin Kullik, head of application engineering at precision tool manufacturer botek Präzisionsbohrtech- nik GmbH, who is providing the necessary single flute drills and pilot tools. With drilling depths of 450 mm (l/d>20), deep hole drilling operations in the field of machining pose the greatest challenge.

The deep holes are drilled into the solid material, with the chambering taking place afterwards. This allows the deep hole drilling tool to be guided continuously through the bore it has created, thereby avoiding guide-free drilling after cavities. The Type 110 single flute drills used for this purpose, which are inexpensive and quickly available thanks to botek‘s rapid production, enable high accuracy in terms of hole diameter and center line, excellent surface quality, and optimal cooling lubricant supply thanks to large internal cooling channels. To create the required drilling guide, botek spiral pilot drills are used for the two smaller drill diameters (12 mm and 16 mm), while the pilot holes for the two large deep holes (30 mm and 40 mm) are made using botek HPC milling cutters.

Thanks to the modern 5-axis machine, the subsequent chambering was also carried out without any problems, meaning that the current status of the billet block could be presented to Philipp Kaess as a surprise gift.

The engine block is to be presented to the public at the "Essen Motor Show" in November, together with the newly manufactured bedplate. It should then become clear whether this will remain a one-off or whether Subi-Performance will produce a larger number of these hard-to-find 5.0-liter engines in the futur.

In this case, the experts at Grob and bo- tek already have solutions for automated small-batch production. The G550 can be expanded with automation equipment that allows unmanned production. botek has single flute drills in its portfolio that feature screw-on interchangeable cutting inserts and guide pads instead of brazed heads, which reduces costs for larger quantities and simplifies series produc- tion due to the consistent tool length.

These solutions, as well as the jointly manufactured V10 engine block, can be viewed at the EMO trade fair in Hanover at the Grob booth. Experts from both companies will also be available at the botek booth to answer any further questions. It is definitely worth a visit.