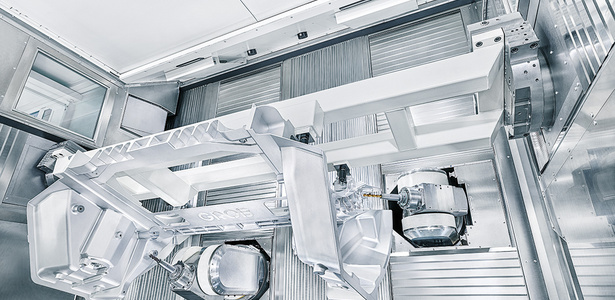

The focus of the trade fair presentation in the field of machining technology is the G920F5 machining center, which was specially developed for processing large-format vehicle components – so-called “mega and giga castings.”

"The G920F sets new standards in machining technology and is a future-proof solution for the automotive industry," explains Carsten König, Head of Machining Technology and Digital Products at GROB.

The machine combines robustness, precision, and flexibility: Thanks to 5-axis technology, even complex components can be efficiently tasked, while the modular design allows individual adaptation to different manufacturing requirements. More than50 machines have already been installed worldwide.

Flexibility and efficiency for a wide range of applications

The G920F5 is suitable for a wide variety of component designs – from frame structure parts to battery housings. Various automation options and the modular design ensure that production can be made efficient, resource-saving, and productive. "Our close cooperation with OEMs and suppliers has enabled us to tailor the G920F5 optimally to the requirements of the industry," emphasizes König.

Further highlights of the G900 series

In addition to the G920F5,the G900 series from GROB includes other machines:

- G920X: Specially developed for machining extruded profiles. With two spindles, two parts can be machined simultaneously, with a machining length of over 2.5 meters.

- G920F4: Designed for the complete task of battery housings. The machine allows parts up to 3,000 mm in length, combining high dynamics with efficient 4-axis task and modular flexibility.

All machines in the G900 series are designed for maximum precision, efficiency, and sustainability, offering solutions for the growing demands of modern automotive production.

Forward-looking technologies for the industry

With the new G900 series, GROB is underlining its leading position in mechanical engineering and demonstrating how modern machining solutions optimize the production of mega and giga castings as well as extruded profiles. Visitors to EMO 2025 will be able to experience the G920F5 live and see its performance for themselves.

"We look forward to presenting the advantages of our latest machine series to our customers and shaping the future of machining technology together," concludes König.

![[Translate to en:] [Translate to en:] G920F5](/fileadmin/_processed_/b/1/csm_Teaser_EMO_Presse_Zerspannunstechnik_2025_861940c56b.jpg)