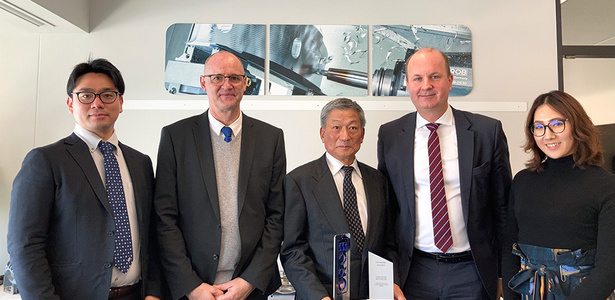

At GROB China, the course was already set two years ago when Ren Hongzhi as the man of the first hour of GROB China, moved to the Supervisory Board of GROB China and his position as CEO was taken over by Marcus Ostler. In over 18 years, Ren Hongzhi has made a significant contribution to GROB's positive development in China and has developed the plant in Dalian with his team into one of the best mechanical engineering companies in the entire country. Sales in China continue to be handled by Biao Wang and Thomas Neubert.

Endo Hideaki, who founded GROB Japan in 2019, is also retiring. He joined GROB in 2013 and served as Key Account Manager for GROB in North America until 2018. Due to his good contacts with Japanese customers in the American market, he was the door opener for GROB and was able to implement several successful projects. His successor will be the long-standing Managing Director of GROB Asia Pacific (GAP), Uwe Wedler. As a proven strategist, Wedler has built up sales in the Asia-Pacific region for GROB and has been particularly successful in Thailand, Vietnam and Malaysia. Since many Japanese OEMs have production in Thailand - comparable to American OEMs in Mexico - the GROB Asia Pacific service organization has supported our GROB branch in Japan for years.

The realignment of GROB Korea will also result in a change in management. Hansung Kim, who worked in Mindelheim for several years and was able to get to know the GROB world there in all areas of machining systems for OEMs and Tier 1, e-mobility and universal machining centers, has been back in Korea since May 2022 and will take over the position of Managing Director on Jan. 1, 2023. His predecessor Park Yeong-Gyu moves to sales and takes over sales of universal machines.

Against the background of the generation change in Asia, we asked GROB CSO Christian Müller a few questions.

What does the generation change mean for GROB?

Christian Müller: It means that we want to position ourselves more broadly with an expanded product range and an adjusted sales strategy in order to generate even more orders for GROB from all markets.

How did GROB prepare for this change?

Hansung Kim trained in Germany for several years. Endo Hideaki worked for GROB in the USA for many years and flew to Japan twice a year for various management meetings. His successor Uwe Wedler has been active for GROB in the Asia-Pacific region for several years and is very familiar with GROB products. As Production Director at GROB in China, Marcus Ostler has practically grown into the new CEO function.

What did you appreciate most about Ren Hongzhi and Endo Hideaki? What were their greatest achievements?

Ren Hongzhi convinced with his absolute market and customer knowledge. He has made GROB China what it is today. Endo Hideaki distinguished himself through his very good networking with Japanese customers and was very loyal to GROB.

In your opinion, what is the development in China, Korea and Japan going to be like?

When the COVID policy is finally relaxed again in China, allowing everyday life to return, the Chinese market with its local for local approach will be perfect for GROB China. We expect many orders, spurred to some extent by the third wave of investment in e-mobility.

In Korea, we must diversify, address all customers and thus generate new orders for GROB South Korea via our broad product range. It remains exciting. In e-mobility, we are increasingly working with key local players to increase our market presence.

In Japan, we recently completed an in-depth market analysis and generated over 650 leads that now need to be worked through. This will boost our business for universal machining centers. We are in good exchange with OEMs to identify e-mobility & machining projects in order to participate in these important projects. This applies to projects both in Japan and overseas.