Derek Schroeder, Universal Machines Sales Supervisor at GROB, offers these four highlights of how the company has managed to stay competitive and keep pace with the ever-changing demands on machine tool builders working in the automotive, aerospace, medical, mold & die, military, and small-scale production markets:

Vertical Integration:

GROB is not just concerned with production or assembly, but with machining, checking, assembly, and more. The company is capable of supplying its customers with integrated solutions, and it does so while building every component of its own machines in-house. This has been a gradual process that has enabled the company to better serve its customers around the world. The Bluffton, OH facility, for example, started in 1990 as a small sales and runoff facility with 30 employees. Now with more than 550 employees, the Bluffton facility manufactures the entire GROB product line in-house. The capacity to invest in vertical integration over the past several decades was made possible by the company’s family-owned status; the company’s profits are continuously re-invested into expansions that serve customers and allow it to keep pace with industry trends.

Apprenticeship model:

GROB’s growth, exemplified in that of its Ohio facility, is not exclusively thanks to its vertical integration. The company also has implemented an apprenticeship program which introduces new workers to every aspect of the company and has grown from 6 to 40 apprentices per year over just two decades. To date, roughly 40% of the Bluffton workforce has been through GROB’s apprenticeship program. Even those employees who do not complete apprenticeships still become familiar with each and every department. As a result, GROB’s customers can get sales, service, and support from people with expertise about the company’s full range of products.

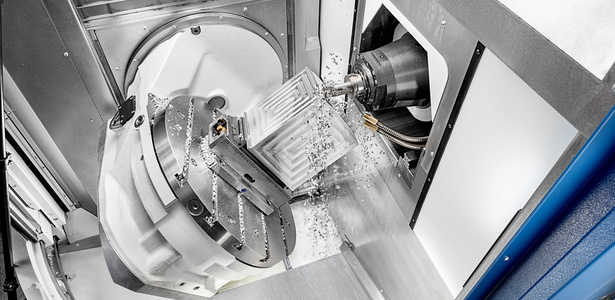

Engineered solutions:

Although GROB has a number of products that are foundational to its success, it is also capable of supplying individualized, engineered solutions to customers that are precisely tailored to their end-use. This focus on retaining and growing with customers ensures that even as trends within the industry shift, GROB can meet its customers’ needs at every stage.

Transfer of knowledge across industries:

Finally, since GROB manufactures machining technology that is used throughout many different industries, the trends that shape industries at the cutting edge can begin to benefitother industries that may be lagging behind. For example, manufacturing products that can machine cutting-edge aerospace materials now will benefit automotive customers in the future once these materials become more mainstream. Likewise, solutions for automation or data management developed for one industry can be applied to others as manufacturing practices evolve.

Schroeder concludes: “Just one of these strategies would not be enough to keep us ahead of the crowd, but we’ve shown a strong commitment to adjusting to change. Through our overall ethic of adaptation and innovation, GROB is demonstrating how machine tool builders can move with and shape the industries we supply.”