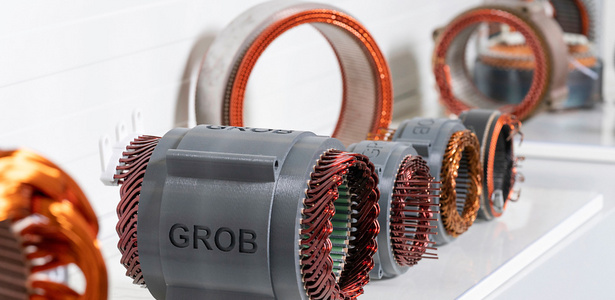

GROB defined four essential technologies where solutions can be offered and produced for the international automotive industry to meet the requirements of the automotive industry in the field of electromobility. This includes machines and systems for the production of electric drives, battery modules, battery packs, also called high-voltage battery systems and battery cells.

GROB – A Full-Service Provider in Electromobility

GROB masters all winding and assembly technologies for the production of the various electric drives and has extensive knowledge and experience in the production of highly complex battery module systems. For example, GROB Mindelheim has delivered eight large production lines for the battery module assembly of prismatic cells and pouch cells for the German automotive industry. In the future, GROB will also develop and produce large-scale systems for the final assembly of complete battery pack systems. In GROB production plants, complex process steps are used to assemble, fix and electrically connect battery modules in large, trough-like housing components. These battery pack systems represent the entire underbody of new electric cars.

When it comes to the construction of so-called gigafactories for battery cell production, GROB has been able to supply state-of-the-art machines and production systems for these groundbreaking technologies for several months. At the same time, GROB is continuing to invest in the development of fuel cell technology so as to be able to offer manufacturing systems for series production in a timely manner.

Expansion of Key Global E-Mobility Markets

Despite the current difficult global situation caused by the coronavirus (especially in China) and the war in Ukraine with its direct consequences for the current global economic development, we have noticed that the demand for e-mobility projects continues to rise, and interest in e-mobility projects remains high. In order to be able to cope with this development, GROB is expanding its capacities in the American and Chinese plants. In addition to ongoing investments in the Mindelheim main plant, the localization efforts at both the GROB plant in Bluffton, OH, and the GROB plant in Dalian, China, are being pushed forward at high pressure so we can serve the key American and Chinese markets local-to-local.

The GROB plants in Mindelheim and Pianezza, Italy, continue to lead the way in electromobility. For example, the winding technology and insertion technology, which are used to draw round wires into the stator via a complex process, are based at GROB Italy, as is rotor production technology. By contrast, GROB Mindelheim develops and produces the stator technologies for rectangular copper wire, also known as hairpin technology and wave winding technology. The technologies of both plants enable GROB to provide all known manufacturing processes for electric drives that are relevant for automotive companies.