In light of the transformation of the automotive industry and the associated effects on component production, GROB has successively expanded and diversified its machining portfolio in recent years. This company strategy, combined with commitment in the area of “electromobility assembly technology”, has proven itself to be consistent and the right choice for GROB. Today, GROB is able to offer its customers a suitable product range with adequate solutions, regardless of this change.

At the in-house exhibition, GROB will present a G520F from the F-series, which demonstrates this differentiation of GROB’s machine portfolio. GROB’s cross slide concept ensures outstanding dynamics in F-series machines. With its 5-axis A/B interference range of 1,500 mm and high stability, the G520F is a typical representative of the crossover series for all important components, from frame structure parts and subframes to battery housings. In the field of frame structure parts, GROB has been a long-standing solution provider for its customers.

“Ten years ago, we decided to create a dedicated machines series, the 'F-Series', in order to even better meet the requirements of these components. This has clearly hit the nerve of the market. We will continue to develop it further and make it even more efficient to continue providing our customers with GROB solutions that live up to our motto ‘one step ahead’,” says Carsten König, GROB Head of Key Account Management for Machining Technology, concerning the success story of the F-Series.

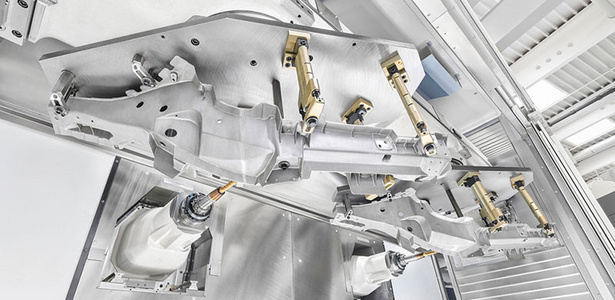

The second exhibit is a G520 (5th generation) that will be presented stripped. This exhibit provides a behind-the-scenes look, so to speak, behind the enclosure to show both the advantages of the 5-axis machine concept that is typical for GROB and its robust design. GROB offers its customers from the automotive sector its G520 two-spindle machining center, an autonomous machine variant for machining two parts in parallel on two to four B-axis rotary tables. The optional adaptation with a pallet changer enables the machining of different components without additional retooling time. Overall, the G520 meets all the requirements of a modern manufacturing system, with maximum flexibility and productivity.

Its unique machine concept is based on two key features: To improve dynamics and rigidity and to achieve a compact configuration according to the modular concept, the motion axes of the G-modules have been divided into tool and part side, or decoupled. The standardized basic principle of GROB machining centers permits the G520 a modularized manufacturing process with shorter throughput times and minimized part costs. In addition, it impresses with high efficiency and is designed for both wet and dry machining, like all G-modules.