With innovative solutions such as hairpin technology and as a full range supplier of systems for the production of electric powertrains, GROB has quickly become the global market leader in electromobility. GROB focuses on powertrain components in the area of system assembly with its emphasis on E-axes/E-motors (EDU Electric Drive Unit) and on battery storage systems, cell assembly, as well as battery module and battery pack assembly. With its machines and systems for e-drives suitable for large-scale production, GROB covers all winding and assembly techniques for stator and rotor production.

Global leader in hairpin technology

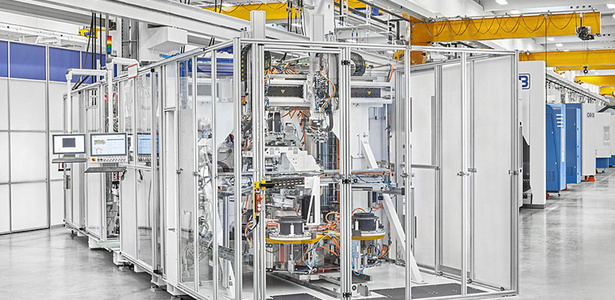

The core of every electric motor is the stator, which has been successfully manufactured for decades using different winding technologies. In the field of traction motors for passenger cars, hairpin winding technology has become the worldwide standard. GROB has successfully evolved into the global market leader (passenger cars, traction motors) in this technology. The bending unit is at the center of the hairpin winding process. It bends the so-called “hairpins” (U-pins) within seconds. In recent years, GROB has developed a method to produce the complete hairpin ring for a stator on a single bending machine. The latest-generation hairpin bending machine, now on display for the first time at a trade fair, is able to halve the pin-to-pin time compared to its predecessor to up to one second. The machine focuses on high-volume projects with cycle times of less than 100 seconds.

Expansion of Key Global E-Mobility Markets

Despite the globally unstable economic situation caused by the war in Ukraine and slowly improving supply chains, GROB continues to experience an undiminished, high demand for and strong interest in e-mobility projects. In addition to ongoing investments in the Mindelheim main plant, the localization efforts at both GROB Bluffton, OH, and GROB Dalian, China, are being pushed forward at high pressure so we can serve the key American and Chinese markets local-to-local.

The GROB plants in Mindelheim, Germany and Pianezza, Italy, continue to play a central role in electromobility. For example, the winding technology and insertion technology, which are used to draw round wires into the stator via a complex process, are based at GROB Italy, as is rotor production technology. By contrast, GROB Mindelheim develops and produces the stator technologies for rectangular copper wire, also known as hairpin and continuous hairpin technology.