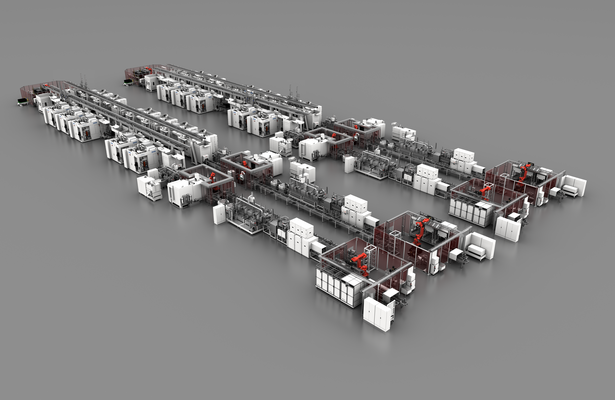

Flexibly adjustable and extremely efficient: The various G-module sizes allow individual manufacturing lines to be configured as required.

Sie wurden automatisch auf unsere englische Website weitergeleitet.

Machining technology

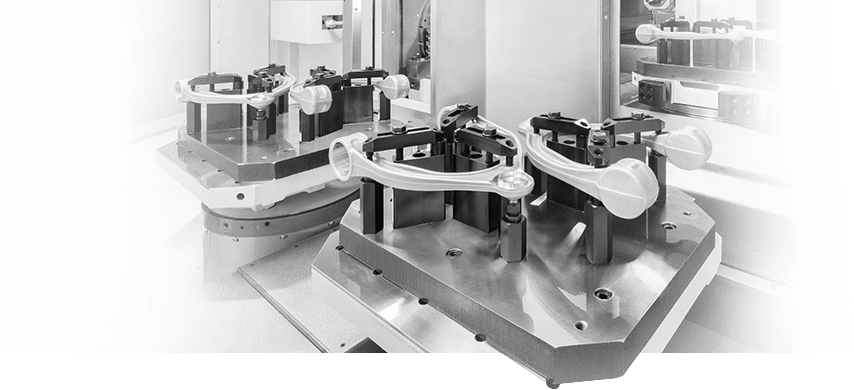

Profound know-how and use of the latest technologies make GROB a recognized expert in the machining technology sector. For perfect implementation of customer specifications, GROB manufactures complete machining solutions in the form of customizable manufacturing lines of the highest quality. These lines consist primarily of modular machining centers and special-purpose machines that are interlinked with the latest automation solutions.

From planning to engineering through to operationally ready delivery and commissioning, GROB offers all core competencies from a single source. This deep vertical integration allows dynamic and customer-specific adjustments to capacities and guarantees an outstanding degree of reliability.

GROB SYSTEMS, Inc.

Phone: +1 (419) 358-9015

E-mail: info@us.grobgroup.com