Mindelheim. GROB automation technology allows you to flexibly adapt to capacities and guarantees pallet and part handling perfectly in tune with your needs.

The GROB product range consists of self-made components, from semi-automatic to fully automatic production with the highest quality standards. Thus, the GROB automation solutions increase the output, reduce the unit costs and enhance the productivity in the company many times over. They, furthermore, ensure an efficient production process, guarantee optimal part handling, and can be optimally adapted to the specific needs of the customer.

GROB robot cell GRC

The newly developed GROB robot cell (GRC) combined with our G-modules offers maximum flexibility and customization for manufacturing needs. With this automation GROB has developed a complete solution from a single source which convinces with a uniform design and coordinated interfaces. The compact design with a shared base frame enables an easy and quick installation. Thanks to the standardized software, the cell can be commissioned in a very short time. The innovative feeding system with part drawers enables longer unmanned production. An automatic clamping fixture and part gripper change is available for different clamping fixtures and part types. The connection to the modern GROB production control software GROB4Automation for flexible planning and management of work orders improves the production sequences. At the same time, parameterizable part geometries ensure short set-up times. The GROB robot cell can be configured with various modules as per customer request e.g. deburring, cleaning, marking, SPC (Statistical Process Control) or a second machine.

Rotary pallet storage system PSS-R light

The new GROB rotary pallet storage system PSS-R light, which is introduced at the Virtual Open House for the first time, is suitable for flexible and economic production for small and medium lot sizes and even individual orders. It has a capacity of up to ten pallets for the pallet size of 320 mm x 320 mm or eight pallets for the pallet size of 400 mm x 400 mm. Its control system is very intuitive and completely integrated into the machine control system. Optionally, the PSS-R light can also be connected to the GROB in-house production control software GROB4Automation and can be retrofitted quickly and easily at any time. It enables the reduction of non-machining times, the increase of machining times and thus significantly enhances the economic viability of the system.

In this way, parts can be clamped during the machining operation and, for example, a variant with ten pallets can be operated unmanned for five hours with an average machining time of just 30 minutes. Thanks to the horizontal spindle and the round front, the operator also has an excellent view into the working area at any time.

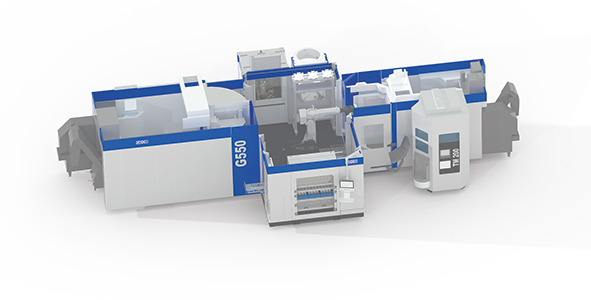

The GROB rotary pallet storage system

| Two sizes with three models each are available PSS-R630: PSS-R5/10/13 -> 3 sizes PSS-R400: PSS-R5/10/15 -> 3 sizes PSS-R630 = G550 PSS-R400 = G350 |

The GROB rotary pallet storage system PSS-R is available in two standard sizes (PSS-R400, PSS-R630) with three different pallet storage capacities each (5, 10, 13 or 15 pallets) for the connection to a universal machining center. In the PSS-R5 version the rotary pallet storage system has five pallet deposits on one level. The PSS-R10 version has ten pallet storage locations on two levels and the PSS-R13 version has thirteen pallet storage locations on three levels. If the pallet at the setup station is added, the available number increases to a maximum of fourteen pallets (PSS-R13). The heart of the rotary pallet storage system builds the centrally located pallet changing device for the simultaneous handling of two pallets. A swivel axis, a lifting axis and a horizontal telescope ensure that the pallets can be changed between the G-module, the setup station and the rack.

Other advantages are the high rigidity of the system and the short pallet changing times. The GROB rotary setup station, already known and proven from the pallet changer system, was transferred to the rotary pallet storage system in terms of functionality and mechanical design. The convenient height of the top edge of the pallet to the floor ensures excellent ergonomics during setup. The round setup station loading door as a typical design feature of the GROB universal machining center has also been included. If it is opened, it completely exposes the setup station area and enables a crane loading of the pallets onto the setup station. As an option, the setup station can be supplemented with a hydraulic clamping system.

The linear pallet storage system (PSS-L)

The linear pallet storage system is a GROB development that complements the product range with an automated, flexible manufacturing system for a wide variety of part machining. It is suitable for stand-alone machines and for interlinking identical machines. With it, up to five machine tools can be connected to a pallet storage racking with a maximum of 87 tool pockets, a significant increase in machine utilization and economic production can be achieved and a longer unmanned production period can be made possible. The production control software GROB4Automation enables a longer unmanned production period with a 24-inch touch screen panel for a visual organization of production orders. Other advantages of the linear pallet storage system include a high storage density with a small footprint, as well as the excellent visibility into the work space and the pallet storage locations.