Mindelheim/Hanover. Against the background of its decades of experience in the manufacture of highly efficient manufacturing and assembly systems and the emerging paradigm shift in the automotive industry, GROB has been investing heavily in the field of electromobility for five years now. A decision that was still risky for many at the time, GROB has now become the market leader and recognized business partner for electric mobility. In addition to Volkswagen, BMW, Daimler and Siemens, the American automobile manufacturers Ford and General Motors and Renault/Nissan in France and Japan, as well as other customers in China are also supplied.

First VW Group Award for E-Mobility

This makes it all the more remarkable for GROB to receive the VW Group Award for E-Mobility in the summer of this year in this still young division for both companies. "Our company has previously been recognized for many outstanding achievements by our employees," said German Wankmiller, Chairman of the Board & CEO of GROB, at the award ceremony. "But never before have we received an award in the "Electromobility" category. An award that particularly honors us and confirms our decision to have invested in this new business segment." The award relates to a major project for an electric drive platform from Volkswagen in China, the largest Asian market.

Extensive product range with strong market response

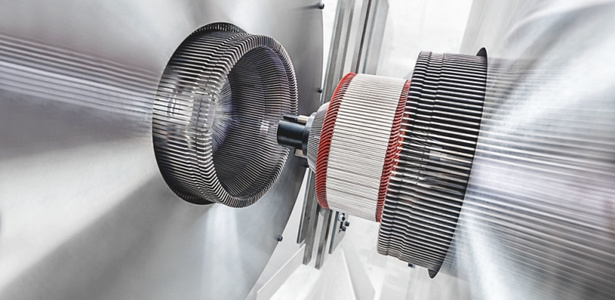

The GROB product portfolio ranges from complex assembly systems for stators, rotors, and electrical machines to the assembly of the complete electrical axis. The range also includes battery module assembly, the construction of a laboratory system for battery cells, and the further development of assembly systems for fuel cells. Particular focus is placed on in-house prototype production of an electric motor with hairpin technology, continuous hairpin, or insertion technology.

A product range that is already being successfully implemented with a high market response. Seven assembly lines with hairpin technology, one assembly line with shaft winding technology, and several assembly lines for the rotor, including assembly of rotor, stator and gearbox, with a total of seven lines, have already been delivered. Since the establishment of GROB Italy in 2016, ten systems with insertion technology have already been implemented and five systems were acquired for battery module assembly. All these successes show that GROB, with its extensive product range in the field of electromobility, has established itself as a reliable partner to the automotive industry for versatile solutions. GROB already generates a quarter of its turnover in this new business segment - and the trend is upwards.

GROB electromobility at EMO

At its EMO booth, GROB will also be presenting in a separate presentation area its expertise in the manufacture of production lines and systems for electric machines and electric motors as well as in the production and assembly of battery cells, modules and packs.